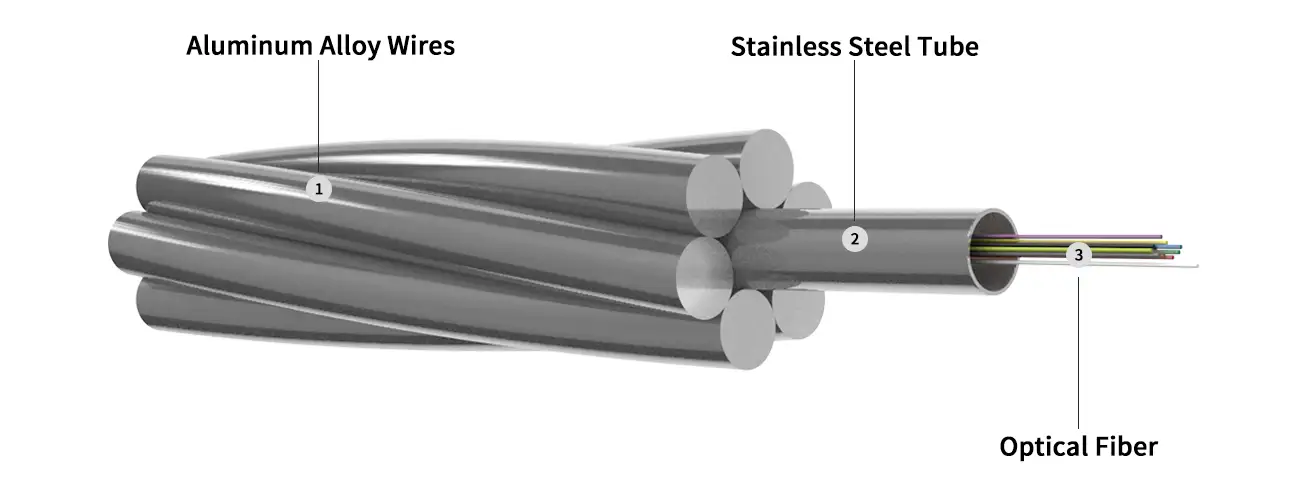

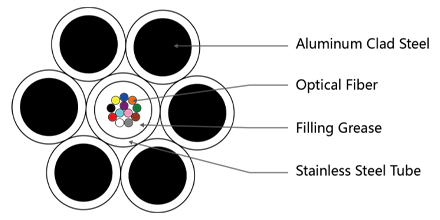

The central stainless steel tube is surrounded by single or double layers of aluminum clad steel wires(ACS) or mix ACS wires and aluminum alloy wires. are the most widely used cables ,their design is fully adapted to the most common electric line needs.

Self-support Aerial installation

| ITU-TG.652 | Characteristics of a single mode optical fiber |

| ITU-TG.655 | Characteristics of a non-zero dispersion-shifted single mode fibers optical |

| EIA/TIA598 B | Col code of fiber optic cables |

| IEC 60794-4-10 | Aerial optical cables along electrical power lines-family specification for OPGW |

| IEC 60794-1-2 | Optical fiber cables-part test procedures |

| IEEE 1138-2009 | IEEE Standard for testing and performance for optical ground wire for use on electric utility power lines |

| IEC 61232 | Aluminum-clad stel wire for electrical purposes |

| IEC 60104 | Aluminum magnesium silicon alloy wire for overhead line conductors |

| IEC 61089 | Round wire concentric lay overhead electrical stranded conductors |

Typical Design for Single Layer

| Specification | Fiber Count | Diameter (mm) | Weight (kg/km) | RTS (KN) | Short Circuit (KA2s) |

| OPGW-50(58;12) | 12 | 9.6 | 344 | 58 | 12 |

| OPGW-75(86.7;30.5) | 24 | 12 | 527 | 86.7 | 30.5 |

| OPGW-70(81.5.6;25.2) | 48 | 11.4 | 480 | 81.5 | 25.2 |

∗ Routine test (in‒process testing according to internal quality plan)

∗ Factory acceptance test (FAT, witnessed by customer)

∗ Type test (only in case of a basic new design, repetition in exceptional cases)

OPGW tests shall be in accordance with applicable standards or agreements between purchaser and manufacturer. As a general rule the tests will be performed according IEC 60794-4-10.However, if necessary tests can be done according to IEEE Std1138.

to an agreement between purchaser and manufacturer.

measured at 1550nm.

With more than 60 OPGW fiber cable designs successfully type-tested, GL FIBER has extensive experience in OPGW qualification. Additionally, our in-house laboratories certify that all cables are manufactured in compliance with the design specifications. GL FIBER' OPGW manufacturing plants are ISO 9001 and 14001 certified and the quality assurance systems are managed accordingly.

1. OEM Manufacturer: GL FIBER focus on manufacturing OPGW cable for more than 20 years, We can OEM OPGW from 8-144 cores, Low loss ITU-T G.652.D/G.655 Fibre, Other special request also supported.

2. Quality Assurance: GL FIBER set up complete, advanced test center, with complete product test equipment and obtaining international qualification certification, controlling the quality of raw materials and finished products. Our OPGW cables products passed the type tests by authoritative institutions China Electric Power Research Institute and Shanghai Electric Cable Research Institute.

3. Supply Performance: GL FIBER now has 20 sets of OPGW optical cable equipments, 200KM/day stable production capacity, We have supplied over 8000 km of OPGW cable to worldwide for 600+ projects.5. 7*24 Online Service: GL FIBER offer perfect pre-sales, sales, post-sales service for our customers 7*24 Online Service.

Besides, for large-scale deployment and international transportation needs, we provide flexible container packaging options - whether it is a standard 20-foot container, suitable for compact space and flexible deployment; or a spacious 40-foot container, which can meet the needs of large-scale projects. For one-stop transportation, we can accurately adapt to ensure the safe arrival of goods.

| Cable Diameter (mm) | Drum Length (m) | Drum Dimensions & Weights | |||||

| D | b | B | d | A | weight | ||

| cm | cm | cm | cm | cm | kg | ||

| 9.0-9.5 | 2000 | 120 | 90 | 110 | 80 | 11 | 200 |

| 3000 | 120 | 90 | 110 | 80 | 11 | 200 | |

| 4000 | 120 | 90 | 110 | 80 | 11 | 200 | |

| 5000 | 130 | 90 | 110 | 80 | 11 | 210 | |

| 9.5-10.0 | 2000 | 120 | 90 | 110 | 80 | 11 | 200 |

| 3000 | 120 | 90 | 110 | 80 | 11 | 200 | |

| 4000 | 130 | 90 | 110 | 80 | 11 | 210 | |

| 5000 | 130 | 90 | 110 | 80 | 11 | 210 | |

| 10.5-11.0 | 2000 | 120 | 90 | 110 | 80 | 11 | 200 |

| 3000 | 120 | 90 | 110 | 80 | 11 | 200 | |

| 4000 | 130 | 90 | 110 | 80 | 11 | 210 | |

| 5000 | 140 | 90 | 110 | 80 | 11 | 220 | |

| 11.5-12.0 | 2000 | 120 | 90 | 110 | 80 | 11 | 200 |

| 3000 | 130 | 90 | 110 | 80 | 11 | 210 | |

| 4000 | 130 | 90 | 110 | 80 | 11 | 210 | |

| 5000 | 140 | 90 | 110 | 80 | 11 | 220 | |

| 12.0-12.5 | 2000 | 120 | 90 | 110 | 80 | 11 | 200 |

| 3000 | 130 | 90 | 110 | 80 | 11 | 210 | |

| 4000 | 140 | 90 | 110 | 80 | 11 | 220 | |

| 5000 | 150 | 90 | 110 | 80 | 11 | 230 | |

| 12.5-13.0 | 2000 | 120 | 90 | 110 | 80 | 11 | 200 |

| 3000 | 130 | 90 | 110 | 80 | 11 | 210 | |

| 4000 | 140 | 90 | 110 | 80 | 11 | 220 | |

| 5000 | 150 | 90 | 110 | 80 | 11 | 230 | |

| 13.0-14.5 | 2000 | 130 | 90 | 110 | 80 | 11 | 210 |

| 3000 | 140 | 90 | 110 | 80 | 11 | 220 | |

| 4000 | 150 | 90 | 110 | 80 | 11 | 230 | |

| 5000 | 160 | 90 | 110 | 80 | 11 | 250 | |