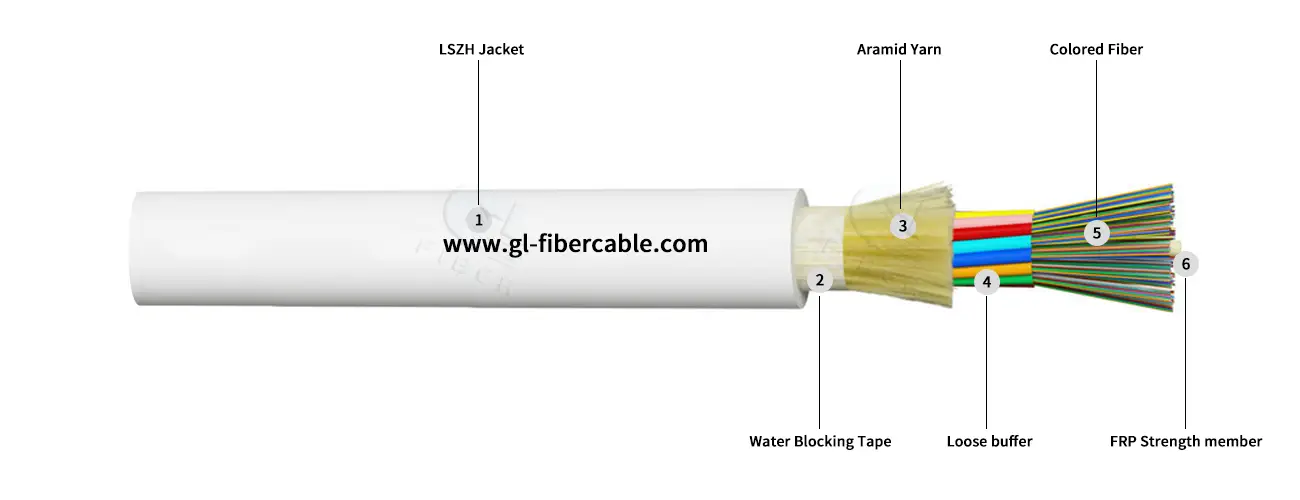

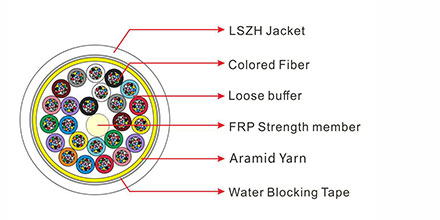

Indoor Micro Tube Fiber Optic Cable is made by placing multiple colored optical fibers (single mode or multimode fibers) in LSZH micro tubes, and spiral twisting multiple unit micro tubes around non-metallic tensile elements (aramid) to wrap a layer of water blocking tape to form a circular cable core. The outer layer of the cable core is effectively reinforced with multiple aramid yarns, and finally a layer of LSZH material is extruded (suitable color strips are extruded according to customer requirements), its purpose is to facilitate laying and construction maintenance identification.

5. The product can adapt to a certain length of Z-shaped conduit and can achieve roundabout wiring;

|

|

G.655 |

50/125μm |

62.5/125μm |

||

|

Attenuation |

@850nm |

|

|

≤3.0dB/km |

≤3.0dB/km |

|

@1300nm |

|

|

≤1.0dB/km |

≤1.0dB/km |

|

|

@1310nm |

≤0.36dB/km |

≤0.36dB/km |

|

|

|

|

@1550nm |

≤0.22dB/km |

≤0.23dB/km |

|

|

|

|

Bandwidth |

@850 |

|

|

≥500MHZ·km |

≥200MHZ·km |

|

@1300 |

|

|

≥1000MHZ·km |

≥600MHZ·km |

|

|

Numerical Aperture |

|

|

|

0.200±0.015NA |

0.275±0.015NA |

|

Cable Cut-off Wavelength |

|

≤1260nm |

≤1480nm |

|

|

|

Fiber Count |

Cable Diameter |

Cable Weight |

Tensile Strength |

Crush Resistance |

Bending Radius |

|

12 |

5.5 |

27 |

400/1000 |

300/1000 |

20D/10D |

|

24 |

7.1 |

45 |

450/1100 |

300/1000 |

20D/10D |

|

48 |

7.7 |

53 |

500/1320 |

300/1000 |

20D/10D |

|

72 |

8.2 |

60 |

500/1320 |

300/1000 |

20D/10D |

|

96 |

8.6 |

68 |

600/1500 |

300/1000 |

20D/10D |

|

144 |

10.5 |

89 |

600/1500 |

300/1000 |

20D/10D |

|

Transportation temperature |

-40℃~+70℃ |

|

Storage temperature |

-40℃~+70℃ |