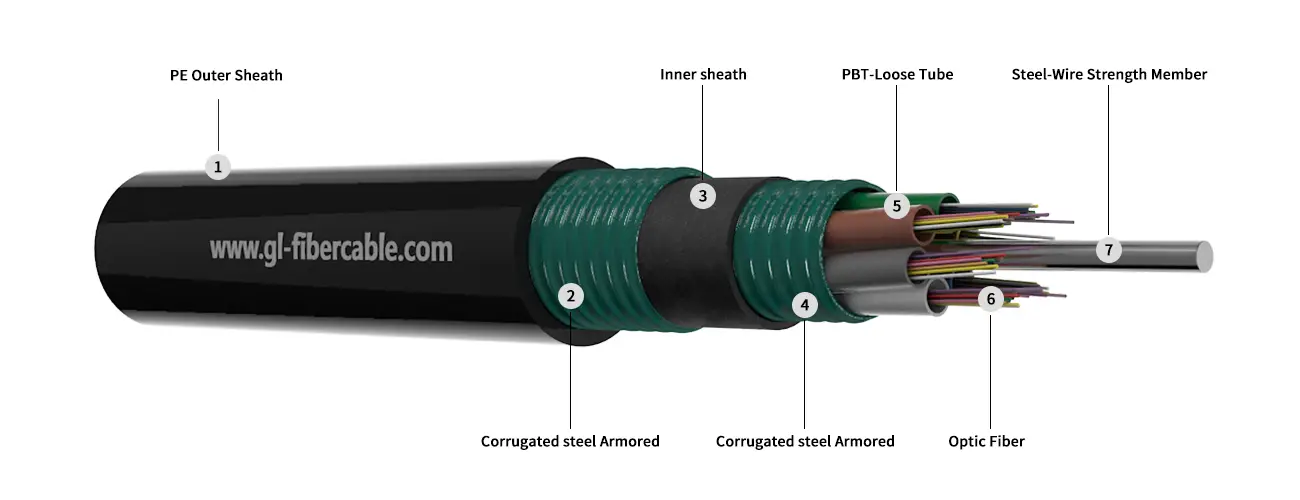

The fibers, 250µm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminate (APL) is applied around the cable core, which is filled with the filling compound to protect it from water ingress. Then the cable core is covered with a thin PE inner sheath. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

Excellent Anti-rodent performance.

Excellent crush resistance

Direct-buried installation and aerial installation.

High water resistance

High crush resistance

Choice Sheath Material

Low attenuation and dispersion

Good flexibility and bending performance.

|

|

G.652.D |

G.655 |

50/125um |

62.5/125um |

|

|

Attenuation |

@850nm |

- |

- |

≤3.0 dB/km |

|

|

|

@1300nm |

- |

- |

≤1.0 dB/km |

|

|

|

@1310nm |

≤0.36 dB/km |

≤0.40 dB/km |

- |

|

|

|

@1550nm |

≤0.22 dB/km |

≤0.23 dB/km |

- |

|

|

Bandwidth |

@850nm |

- |

- |

≥500 MHz · km |

|

|

|

@1300nm |

- |

- |

≥1000 MHz · km |

|

|

Polarization

mode

dispersion

|

lndividual fibre |

≤0.20 ps/√km |

≤0.20 ps/√km |

- |

|

|

|

Design link value

(M=20,Q=0.01%)

|

≤0.1 ps/√km |

≤0.1 ps/√km |

- |

|

|

Item |

Contents |

Value |

|||||||||||||||||||||||

|

Fiber Count |

24 |

48 |

72 |

96 |

144 |

288 |

|||||||||||||||||||

|

Loose Tube |

No. of tubes*fibres per tube |

4*6 |

4*12 |

6*12 |

8*12 |

12*12 |

24*12 |

||||||||||||||||||

|

Outer diameter (mm) |

1.9 |

2.4 |

2.4 |

2.4 |

2.4 |

2.4 |

|||||||||||||||||||

|

Central strength member |

Material |

Phosphated steel wire |

|||||||||||||||||||||||

|

Diameter (mm) |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

|||||||||||||||||||

|

Coated CSM diameter (mm) |

- |

2.6 |

2.6 |

4.2 |

7.4 |

4.8 |

|||||||||||||||||||

|

Water Blocking material |

Material |

Cable filling compound |

|||||||||||||||||||||||

|

Armor |

Material |

Corrugated steel tape |

|||||||||||||||||||||||

|

Inner Sheath |

Thickness (mm) |

Nominal:1.0 |

|||||||||||||||||||||||

|

Anti-Rodent Armor |

Material |

Corrugated steel tape |

|||||||||||||||||||||||

|

Outer Sheath |

Thickness (mm) |

Nominal:2.0 |

|||||||||||||||||||||||

|

Cable diameter(mm)Approx. |

14.2 |

15.7 |

15.7 |

17.5 |

21.0 |

23.0 |

|||||||||||||||||||

|

Cable weight(kg/km)Approx. |

230 |

265 |

265 |

305 |

390 |

460 |

|||||||||||||||||||

|

Operating temperature range(℃) |

-40~+70 |

||||||||||||||||||||||||

|

Tensile Strength Short/ Long Term(N) |

3000/1000 |

||||||||||||||||||||||||

|

Crush resistanoe short/long term (N/100mm) |

3000/1000 |

||||||||||||||||||||||||

|

The colour arrangement of fibre and tube is specified in the colour identification table. |

|||||||||||||||||||||||||

|

Other structure and fibre count are also available according to customer requirements. |

|||||||||||||||||||||||||

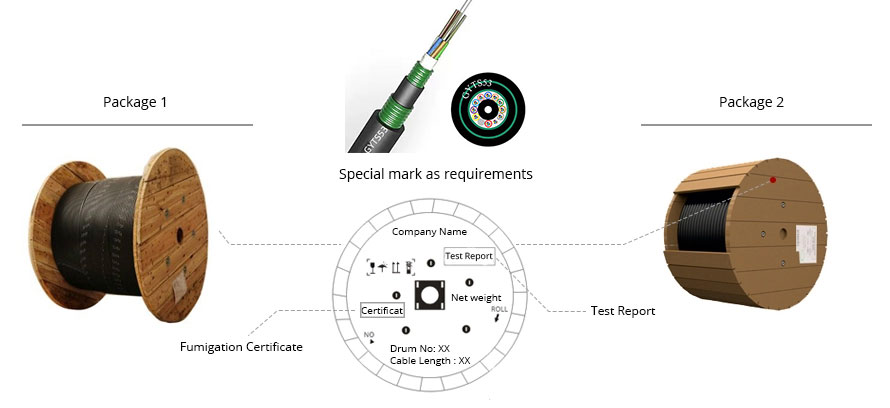

Drum length: Standard drum length is 2,000m ± 2%; as required

Drum length; Gross/net weight;

The fibers, 250µm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminate (APL) is applied around the cable core, which is filled with the filling compound to protect it from water ingress. Then the cable core is covered with a thin PE inner sheath. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

Excellent Anti-rodent performance.

Excellent crush resistance

Direct-buried installation and aerial installation.

High water resistance

High crush resistance

Choice Sheath Material

Low attenuation and dispersion

Good flexibility and bending performance.