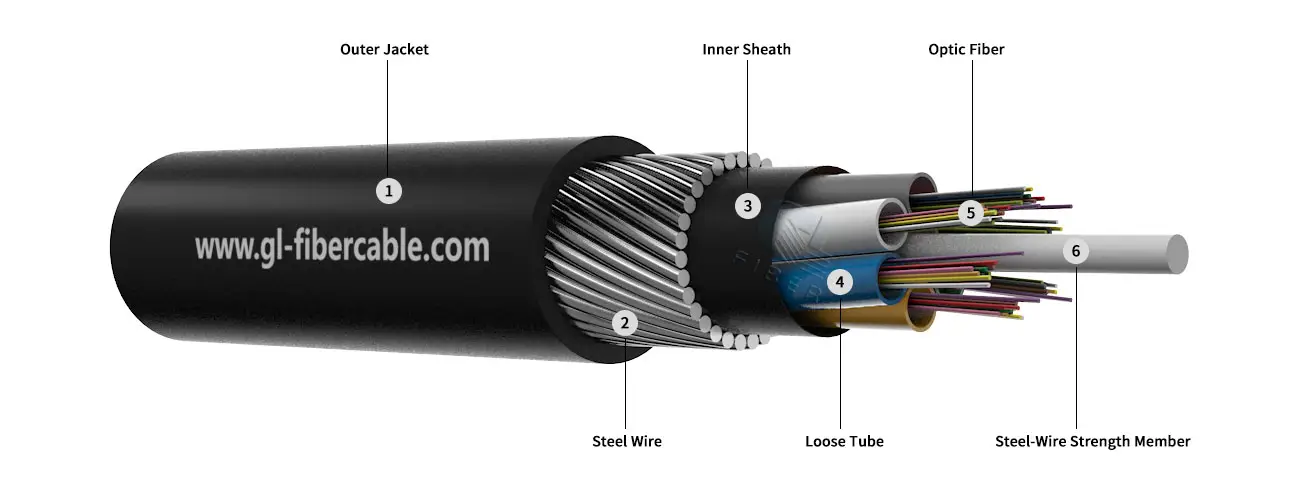

The loose tubes are made of high modulus plastics (PBT) and filled with water resistant filling gel. Loose tubes are stranded around the metallic central strength member, cable core is filled with cable filling compound. The corrugated aluminum tape is longitudinally applied over the cable core, and combined with polyethylene (PE) inner sheath. Galvanized steel wires are stranded around inner sheath, and then extruded with PE outer sheath.

1. Underwater communication fields such as rivers and lakes.

2. Conmmunication areas such as climbing and burying.

1. Full-section water-blocking structure ensures good water and moisture re sistance

2. The loose tube is filled with special grease to critically protect the fiber

3. The phosphating steel wire center reinforcement member has high modulus and corrosion resistance

4. Vertically wrapped double-sided wrinkled aluminum strip, fine round wire wrapped around the package to ensure the mechanical compression, tensile, anti rodent , elastic energy of the c able, to meet the application requirements of vertical burying and underwater laying

5. The product has a service life of more than 30 years

Comply with standard IEC 60794-1.

|

Fiber Count

|

Structure | Fibers Per Tube | Loose Tube Diameter (mm) | CSM Diameter/Pad Diameter (mm) |

Crush Resistance Long/Short Term N/100MM |

Nominal Thickness of Outer Jacket ( mm) | Cable Diameter (mm) | Cable Weight (kg/km) |

| 12 | 1+5 | 6 | 1.7±0.1 | 1.4/1.4 | 5000N/100mm | 1.8 | 13.0±0.5 | 270 |

| 24 | 1+5 | 6 | 1.7±0.1 | 1.4/1.4 | 5000N/100mm | 1.8 | 13.0±0.5 | 271 |

| 36 | 1+6 | 6 | 1.7±0.1 | 1.8/1.8 | 5000N/100mm | 1.8 | 13.0±0.5 | 292 |

| 48 | 1+5 | 12 | 2.0±0.1 | 1.4/1.4 | 5000N/100mm | 1.8 | 13.7±0.5 | 295 |

| 72 | 1+6 | 12 | 2.0±0.1 | 2.0/2.0 | 5000N/100mm | 1.8 | 14.4±0.5 | 335 |

| 96 | 1+8 | 12 | 2.0±0.1 | 1.8/3.5 | 5000N/100mm | 1.8 | 16.0±0.5 | 389 |

| 144 | 1+12 | 12 | 2.0±0.1 | 1.8/6.3 | 5000N/100mm | 1.8 | 19.4±0.5 |

601 |

GL FIBER provides a full range of customized fiber optic cable packaging solutions carefully matching your unique needs.

Starting with customized packaging printing, your brand LOGO, safety warnings or specific information can be printed directly on the packaging carton boxes and packaging spool, which not only enhances the brand image, but also ensures the accuracy and efficiency of on-site identification.

Whether it is wooden reel that pursue natural texture and environmental protection concepts, or iron reel that emphasize sturdiness and durability, we present them all to ensure the best protection of optical cables during transportation and storage.

Besides, for large-scale deployment and international transportation needs, we provide flexible container packaging options - whether it is a standard 20-foot container, suitable for compact space and flexible deployment; or a spacious 40-foot container, which can meet the needs of large-scale projects. For one-stop transportation, we can accurately adapt to ensure the safe arrival of goods.

| Cable Type | Length (M) | Fiber Count | Outer Diameter (mm) | |||||

| 1000M | 2000M | 3000M | 4000M | 5000M | ||||

| GYTA33 | Net Weight (kg) | 115 | 230 | 345 | 460 | 575 | 2-60 fibers | 10.5mm |

| Gross Weight (kg) | 130 | 260 | 390 | 520 | 650 | |||

| Reel Size (cm) | 60*60 | 80*70 | 100*70 | 110*70 | 120*70 | |||

| Net Weight (kg) | 125 | 250 | 375 | 500 | 625 | 62-72 fibers | 11.8mm | |

| Gross Weight (kg) | 145 | 275 | 405 | 535 | 665 | |||

| Reel Size (cm) | 70*60 | 90*70 | 100*70 | 120*70 | 120*80 | |||

| Net Weight (kg) | 185 | 370 | 555 | 740 | 925 | 74-96 fibers | 13.5mm | |

| Gross Weight (kg) | 200 | 400 | 600 | 800 | 1000 | |||

| Reel Size (cm) | 80*70 | 100*70 | 120*70 | 130*80 | 140*80 | |||

| Net Weight (kg) | 270 | 540 | 810 | 1080 | 1350 | 144 fibers | 16mm | |

| Gross Weight (kg) | 300 | 600 | 900 | 1200 | 1500 | |||

| Reel Size (cm) | 90*70 | 120*70 | 140*80 | 150*80 | 160*80 | |||

| Net Weight (kg) | 320 | 640 | 1920 | 288 fibers | 20mm | |||

| Gross Weight (kg) | 350 | 700 | 560 | |||||

| Reel Size (cm) | 110*70 | 140*80 | 160*80 | |||||

Above reel size is: diameter * width (cm)