The rapid rollout of 5G networks demands high-speed, low-latency, and scalable backhaul solutions. Two fiber optic technologies—

All-Dielectric Self-Supporting (ADSS) cables and Air Blown micro cables (including blown micro cables)—have emerged as leading contenders. While both aim to address 5G’s infrastructure needs, their cost structures, deployment efficiencies, and suitability for specific scenarios spark intense debate among network planners. This article dissects their strengths, limitations, and ideal use cases in the 5G era.

1. Technology Overview

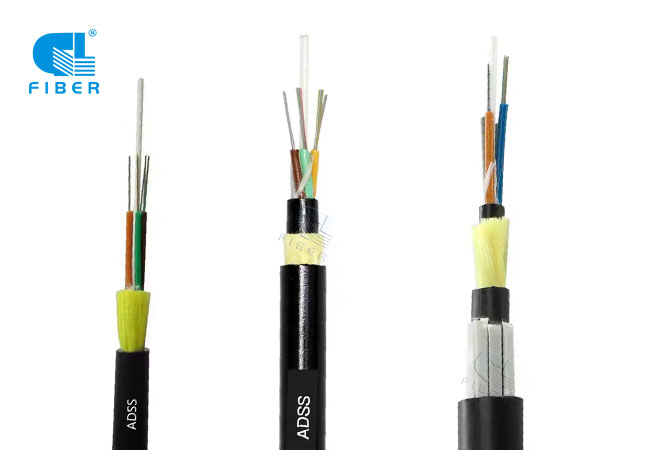

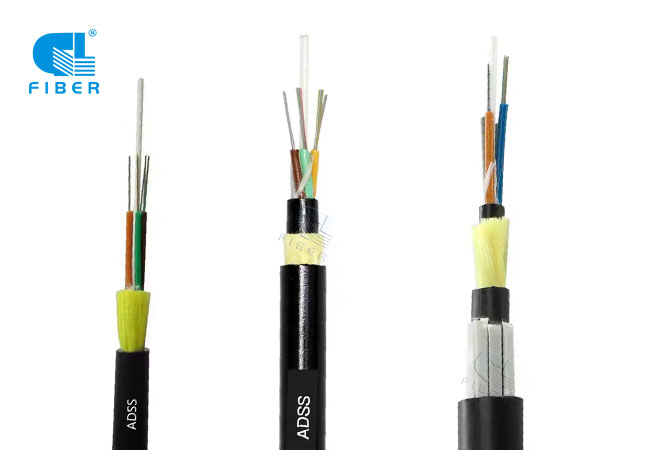

ADSS Cables

Structure: Non-metallic, lightweight design with dielectric strength members (e.g., aramid yarn) and weather-resistant jackets (PE/AT).

Key Advantage: Installed on existing power lines or utility poles without requiring separate support structures, avoiding electromagnetic interference (EMI).

Typical Use: Rural/suburban areas, power grid corridors, and regions with established electrical infrastructure.

Structure: Ultra-slim, lightweight cables (often ≤10mm diameter) designed for installation in microducts using air-assisted blowing.

Key Advantage: High fiber density and rapid deployment in congested urban ducts or new microduct networks.

Typical Use: Dense urban areas, underground conduit systems, and last-mile FTTx networks.

2. Cost Analysis

Initial Deployment Costs

ADSS Cables:

Lower Civil Works Costs: Leverages existing power poles/towers, eliminating the need for new trenches or ducts.

Material Costs: Higher per-meter cable cost due to robust construction, but savings from reduced infrastructure investment.

Labor Costs: Requires specialized teams for aerial installation and tensioning but avoids complex permitting in urban zones.

Micro Cables:

Duct Infrastructure Dependency: Requires pre-existing or newly installed microducts, raising upfront costs for duct networks.

Material Costs: Lower per-meter cable cost, but microducts and blowing equipment add expenses.

Labor Costs: Faster installation via blowing (up to 2km/day) reduces labor time, ideal for high-density areas.

Verdict: ADSS excels in areas with power infrastructure;

micro fiber cables win in duct-rich urban zones.

Long-Term Maintenance Costs

ADSS Cables:

Prone to environmental wear (e.g., UV exposure, ice/wind load) but designed for 25–30-year lifespans.

Maintenance costs rise in harsh climates (e.g., re-tensioning after storms).

Micro Cables:

Protected within ducts, minimizing environmental damage.

Easier upgrades: New fibers can be blown into existing microducts without replacing cables.

3. Deployment Efficiency

Speed & Flexibility

ADSS Cables:

Pros: Quick to deploy on existing power lines; avoids urban red tape.

Cons: Limited to routes with power infrastructure; spans require precise sag calculations.

Micro Cables:

Pros: Rapid installation in pre-deployed ducts; scalable for future fiber counts.

Cons: Microduct networks must be built first, delaying timelines in greenfield projects.

5G-Specific Challenges

Small Cell Density: 5G requires ~10x more nodes than 4G. Micro cables adapt better to dense urban grids.

Power Grid Integration: ADSS seamlessly aligns with power utilities’ infrastructure, ideal for macro-cell backhaul.

4. Case Studies

ADSS Success: Rural 5G in India

Scenario: Rolling out 5G to villages using existing electricity poles.

Outcome: ADSS reduced deployment costs by 40% compared to trenching, accelerating coverage in low-income regions.

Micro Cable Dominance: Tokyo’s Urban 5G

Scenario: Upgrading backhaul for thousands of small cells in a duct-congested metropolis.

Outcome: Blown micro cables achieved 60% faster deployment than traditional cables, minimizing street disruptions.

5. Future Outlook

Hybrid Approaches: Combining ADSS for backbone links and micro cables for last-mile small cells.

Material Innovations: Lighter ADSS designs and fire-resistant microducts to cut costs further.

Automation: AI-powered route planning and robotic blowing/installation to enhance efficiency.

Conclusion

The ADSS vs. micro cable debate hinges on geography, infrastructure, and project scale.

ADSS cables offer cost savings in power-rich, low-density regions, while blown micro cables deliver speed and scalability in urban 5G megaprojects. As 5G evolves, a balanced strategy leveraging both technologies will likely dominate, ensuring operators meet coverage, capacity, and budget goals without compromise.