In the competitive world of fiber optic networks, achieving cost-efficiency requires a strategic balance between upfront investments and long-term operational expenses. All-Dielectric Self-Supporting (ADSS) cables, widely used in power line communications and 5G backhaul, exemplify this challenge. While their durability and ease of installation make them attractive, network operators often grapple with optimizing initial deployment costs against decades of maintenance needs. This article explores actionable strategies to strike this balance, ensuring ADSS cables deliver maximum ROI over their 25–30-year lifespan.

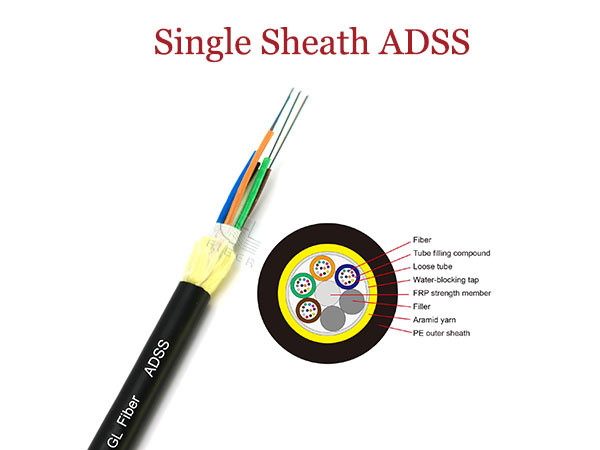

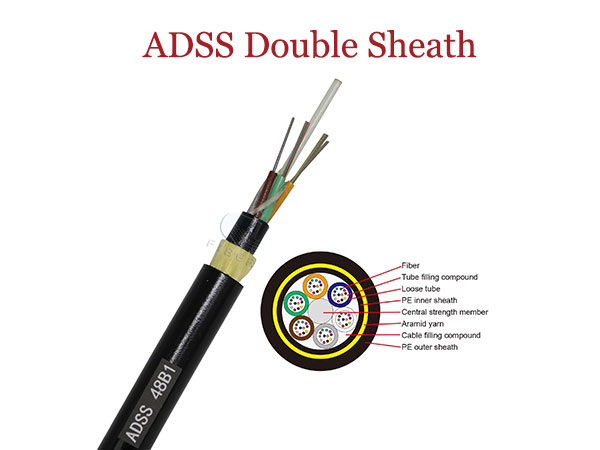

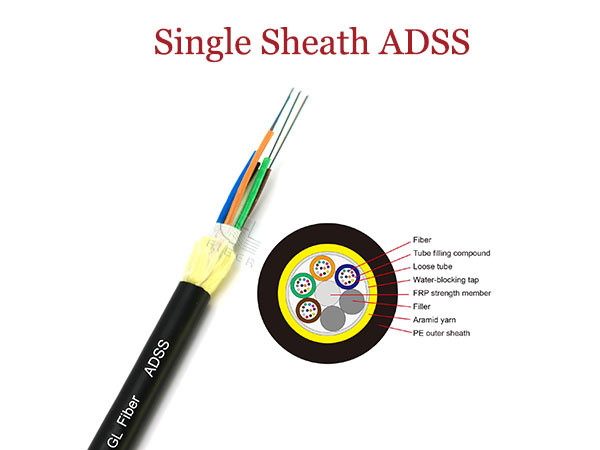

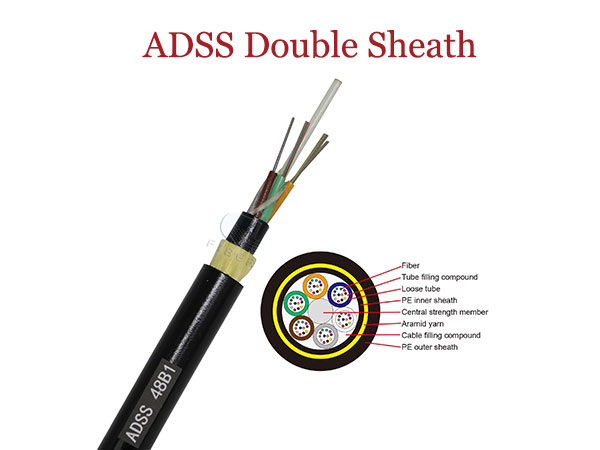

1. Optimize Cable Design for Longevity

Material Selection:

Invest in high-quality, UV-resistant polyethylene (PE) or anti-tracking (AT) jackets to minimize environmental degradation. Though premium materials raise initial costs, they reduce maintenance frequency and extend service life.

Bend-Insensitive Fibers:

Use G.657.A2/B3 fibers to prevent micro-bend losses, avoiding costly signal repairs in complex installations.

Cost-Saving Tip: Partner with manufacturers to customize cable designs for specific environmental conditions (e.g., high humidity, ice zones).

2. Streamline Installation Practices

Pre-Installation Surveys:

Conduct thorough route assessments to identify risks like extreme wind zones or proximity to high-voltage lines. Precise sag and tension calculations prevent over-engineering and future rework.

Modular Accessories:

Use pre-assembled hardware (e.g., suspension clamps, vibration dampers) to accelerate installation and reduce labor costs.

Case Study: A European utility provider cut installation time by 30% using pre-engineered ADSS kits, lowering upfront costs by 15%.

3. Adopt Predictive Maintenance Technologies

Fiber Monitoring Systems:

Deploy OTDR (Optical Time-Domain Reflectometer) and DTS (Distributed Temperature Sensing) for real-time fault detection, enabling proactive repairs before outages occur.

AI-Powered Analytics:

Integrate machine learning tools to predict cable aging patterns and schedule maintenance during low-impact periods.

ROI Insight: Predictive maintenance reduces emergency repair costs by up to 40% and extends cable lifespan by 5–7 years.

4. Leverage Hybrid Deployment Models

Strategic Span Lengths:

Balance shorter spans (lower initial tensioning costs) with longer spans (fewer support structures) based on terrain and budget.

Phased Rollouts:

Prioritize high-value routes (e.g., 5G hubs, smart grid corridors) for early ADSS deployment, deferring low-traffic areas until ROI is realized.

5. Calculate Total Cost of Ownership (TCO)

Initial Costs: Cable, hardware, labor, permits.

Lifecycle Costs: Inspections, repairs, upgrades, downtime losses.

TCO Formula:

TCO = Initial Costs + (Annual Maintenance × Lifespan) – Residual Value

Example: A 10km ADSS project with a 50kinitialcostand2k/year maintenance over 25 years has a TCO of 100k.Upgradingtoacorrosion−resistantjacket(+10k initial) could slash maintenance to 1k/year,loweringTCOto85k.

6. Partner with Certified Suppliers

Warranty Programs:

Choose suppliers offering extended warranties covering material defects and environmental wear.

Training Support:

Ensure installers and maintenance teams receive OEM-certified training to avoid costly errors.

7. Environmental and Regulatory Compliance

Future-Proof Designs:

Align with IEC 60794 and IEEE 1138 standards to avoid fines or retrofits due to regulatory changes.

Eco-Friendly Materials:

Halogen-free jackets and recyclable components minimize disposal costs and align with ESG goals.

Conclusion: Achieving Cost Balance

Balancing ADSS cable costs isn’t about cutting corners—it’s about smart investments in quality, technology, and planning. By prioritizing durable materials, predictive maintenance, and TCO-driven decisions, operators can reduce lifetime expenses by 20–30% while ensuring network reliability.

Ready to Optimize Your ADSS Project?

Contact our experts today for a free TCO analysis and customized solutions tailored to your budget and operational goals!