Description:

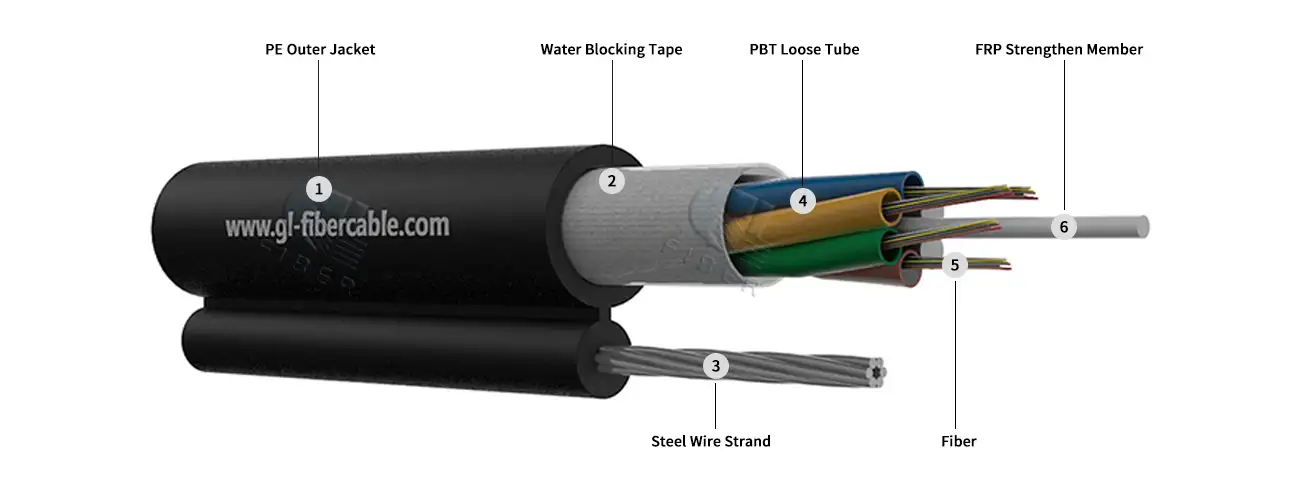

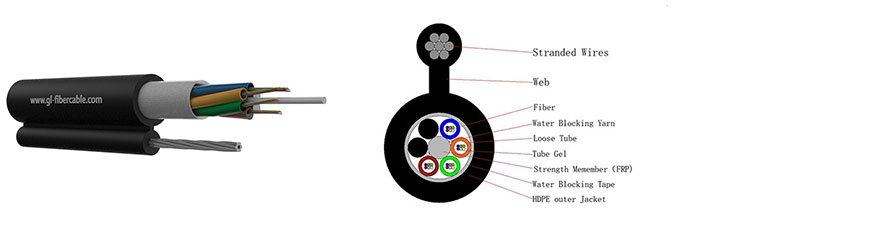

The fibers are placed in a loose tube made of high modulus plastic. The tubes are filled with a water-resistant filling compound. A FRP locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular cable core. After wrapped with the water blocking tape, this part of cable accompanied with the stranded wires as the supporting part are completed with a polyethylene (PE) sheath to be figure 8 structure. This kind of cable is specifically applied for self-supporting aerial installation.

Cable Section:

Application:

* Adapted to outdoor distribution.

* Suitable for aerial.

* Long distance and local area network communication.

Main Features:

1. Low loss, low dispersion.

2. Reasonable design, accurate residual length control and cable forming process, so that the optical cable has mechanical and environmental performance.

3. Non-metal cable core, with strong anti-electromagnetic interference ability.

4. Compact structure, light weight, self-supporting erection.

| Fiber number | Cable | Cable net | Min. bending | Max. tensile | Max. crush | |||

| diameter(mm) | weight (kg/km) | radius(mm) | strength(N) | pressure(N/100mm) | ||||

| 30 and below | 9.5x19.1 | 159 | 100 | 200 | 6000 | 2000 | 1000 | 300 |

| 32~36 | 10.1x19.7 | 170 | 110 | 220 | 6000 | 2000 | 1000 | 300 |

| 38~60 | 10.8x20.4 | 179 | 110 | 220 | 6000 | 2000 | 1000 | 300 |

| 62~72 | 11.6x21.2 | 195 | 120 | 240 | 6000 | 2000 | 1000 | 300 |

| 74~84 | 12.4x22.0 | 208 | 130 | 260 | 6000 | 2000 | 1000 | 300 |

| 86~96 | 13.1x22.7 | 222 | 140 | 280 | 6000 | 2000 | 1000 | 300 |

| 98~108 | 13.9x23.5 | 238 | 140 | 280 | 6000 | 2000 | 1000 | 300 |

| 110~120 | 15.7x24.3 | 255 | 150 | 300 | 6000 | 2000 | 1000 | 300 |

| 122~132 | 15.5x25.1 | 273 | 160 | 320 | 6000 | 2000 | 1000 | 300 |

| 134~144 | 16.2x25.8 | 290 | 170 | 340 | 6000 | 2000 | 1000 | 300 |

| Messenger wire Diameter: | ø1.2mmx7 steel wire strand | |||||||

| Operating temperature | -40~+60℃ | |||||||

GL FIBER provides a full range of customized fiber optic cable packaging solutions carefully matching your unique needs.

Starting with customized packaging printing, your brand LOGO, safety warnings or specific information can be printed directly on the packaging carton boxes and packaging spool, which not only enhances the brand image, but also ensures the accuracy and efficiency of on-site identification.

Whether it is wooden reel that pursue natural texture and environmental protection concepts, or iron reel that emphasize sturdiness and durability, we present them all to ensure the best protection of optical cables during transportation and storage.

Besides, for large-scale deployment and international transportation needs, we provide flexible container packaging options - whether it is a standard 20-foot container, suitable for compact space and flexible deployment; or a spacious 40-foot container, which can meet the needs of large-scale projects. For one-stop transportation, we can accurately adapt to ensure the safe arrival of goods.

| Cable Type | Length (M) | Fiber Count | Outer Diameter (mm) | |||||

| 1000M | 2000M | 3000M | 4000M | 5000M | ||||

| GY(F)TC8S | Net Weight (kg) | 180 | 360 | 540 | 720 | 900 | 2-60 fibers | 9MMx16mm |

| Gross Weight (kg) | 210 | 400 | 600 | 790 | 980 | |||

| Reel Size (cm) | 80*70 | 100*70 | 120*70 | 130*70 | 140*80 | |||

Above reel size is: diameter * width (cm)