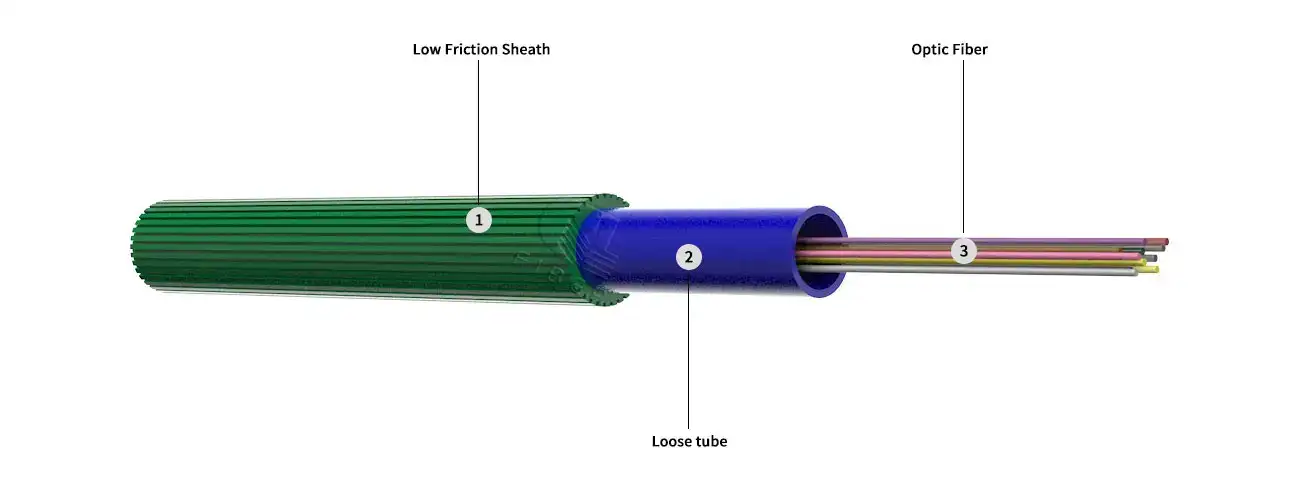

SFU Air Blown Mini Cable (MINI) is small size, light weight, enhanced surface outer sheath fiber unit designed for blowing into micro tube bundles by air flow. The outer thermoplastic layer provides a high level of protection and excellent installation properties. It is usually applied in FTTX.

GL FIBER supplies various types of air blown cable. Its main product is central tube air blown cable and layer stranding air blow cable which has absolutely technical advantage in China and equivalent air blown performance as Europe products.

1. General

1.1. This specification covers the requirements for the supply of single-mode optical fiber cables.

1.2. The single mode optical fiber cable comply with the requirements of this specification and generally meet any latest relevant ITU-T Recommendation G.652D and G657A1.

|

Optics Specifications |

|||

|

Attenuation(dB/km) |

@1310nm |

≤0.34db/km |

|

|

@1383nm (after hydrogen aging) |

≤0.32db/km |

||

|

@1550nm |

≤0.20db/km |

||

|

@1625nm |

≤0.24db/km |

||

|

Dispersion |

@1285nm~1340nm |

-3.0~3.0ps/(nm*km) |

|

|

@1550nm |

≤18ps/(nm*km) |

||

|

@1625nm |

≤22ps/(nm*km) |

||

|

Zero-Dispersion wavelength |

1300~1324nm |

||

|

Zero-Dispersion slope |

≤0.092ps/(nm2*km) |

||

|

Mode field diameter @ 1310nm |

9.2±0.4μm |

||

|

Mode field diameter @ 1550nm |

10.4±0.8μm |

||

|

PMD |

Max. value for fiber on the reel |

0.2ps/km 1/2 |

|

|

Max. Designed value for link |

0.08ps/km 1/2 |

||

|

Cable cutoff wavelength,λ cc |

≤1260nm |

||

|

Effective group index(Neff)@1310nm |

1.4675 |

||

|

Effective group index(Neff)@1550nm |

1.4680 |

||

|

Macro-bend loss(Φ60mm,100 turns)@1550nm |

≤0.05db |

||

|

Back scatter characteristic(@1310nm&1550nm) |

|||

|

Point discontinuity |

≤0.05db |

||

|

Attenuation uniformity |

≤0.05db/km |

||

|

Attenuation coefficient difference for bi-directional measurement |

≤0.05db/km |

||

|

Geometrical characteristics |

|||

|

Cladding diameter |

125±1μm |

||

|

Cladding non-circularity |

≤1% |

||

|

Core/cladding concentricity error |

≤0.4μm |

||

|

Fiber diameter with coating(uncolored) |

245±5μm |

||

|

Cladding/coating concentricity error |

≤12.0μm |

||

|

Curl |

≥4m |

||

|

Mechanical characteristic |

|||

|

Proof test |

0.69GPa |

||

|

Coating strip force(typical value) |

1.4N |

||

|

Dynamic stress corrosion susceptibility parameter(typical value) |

≥20 |

||

|

Environmental characteristics(@1310nm&1550nm) |

|||

|

Temperature induced attenuation(-60~+85℃) |

≤0.5dB/km |

||

|

Dry heat induced attenuation(85±2℃,30days) |

≤0.5dB/km |

||

|

Water immersion induced attenuation(23±2℃,30days) |

≤0.5dB/km |

||

|

Damp heat induced attenuation(85±2℃,RH85%,30days) |

≤0.5dB/km |

||

|

|

Description |

G657A1 |

||

|

|

|

Standard |

||

|

Optical |

Attenuation coefficient |

1310nm |

≤0.34 |

|

|

|

|

1383nm |

≤0.35 |

|

|

|

|

1550nm |

≤0.2 |

|

|

|

|

1625nm |

≤0.23 |

|

|

|

Attenuation inhomogeneity |

1310nm、1550nm |

≤0.05 |

|

|

|

Attenuation discontinuity |

1310nm、1550nm |

≤0.03 |

|

|

|

Wavelength attenuation characteristics |

1288~1330nm |

≤0.05 |

|

|

|

|

1525~1575nm |

≤0.05 |

|

|

|

Dispersion characteristic |

The zero dispersion wavelength nm |

1300~1324 |

|

|

|

|

Zero dispersion slope |

≤0.092 |

|

|

|

|

1288~1339nm |

≤3.5 |

|

|

|

|

1271~1360nm |

≤5.3 |

|

|

|

|

1550nm |

≤18 |

|

|

|

|

1625nm |

≤22 |

|

|

|

The polarization mode dispersion of the fiber |

≤0.1 |

||

|

|

Fiber cutoff wavelength |

≤1260 |

||

|

|

Macro bending loss (10 laps,30mm) |

1550nm |

≤0.03dB |

|

|

|

(10 laps,30mm) |

1625nm |

≤0.1dB |

|

|

|

(1 lap,20mm) |

1550nm |

≤0.1dB |

|

|

|

(1 lap,20mm) |

1625nm |

≤0.2dB |

|

|

|

(1 lap,15mm) |

1550nm |

≤0.5dB |

|

|

|

(1 lap,15mm) |

1625nm |

≤1.0dB |

|

|

|

Mode field diameter |

1310nm |

8.6±0.4 |

|

|

dimension parameter |

Warp degrees |

|

≥4.0 |

|

|

|

Cladding diameter |

|

125 ± 0.7 |

|

|

|

Core/package concentricity |

|

≤0.5 |

|

|

|

Cladding non-circularity |

|

≤1.0% |

|

|

|

Coating diameter |

|

243± 5 |

|

|

|

Coating concentricity |

|

≤8 |

|

|

|

Coating roundness |

|

≤3% |

|

|

mechanical property |

Strain |

|

≥1.05% |

|

|

|

Tensile strength(10m) |

15% Weber fracture probability |

2.76 |

|

|

|

|

50% Weber fracture probability |

3.45 |

|

|

|

Fatigue parameters Nd |

|

≥ 22 |

|

|

|

Coating peak stripping force N |

|

1.0~8.9 |

|

|

|

Coating average stripping force N |

|

1.0~5.0 |

|

|

Environmental performance |

Additional damping temperature cycle (-60℃ ~ +85℃) dB/km@1310nm,1550nm, 1625 nm |

≤ 0.05 |

||

|

|

Wet and heat aging (+85±2℃, 85%RH,30 days) dB/km@1310nm, |

≤ 0.05 |

||

|

|

High temperature aging(85±2℃,30 days ) dB/km @1310nm,1550 |

≤ 0.05 |

||

|

|

Additional attenuation of flooding (23±2℃,30 days ) dB/km @1310nm,1550 |

≤ 0.05 |

||

|

Cable Type |

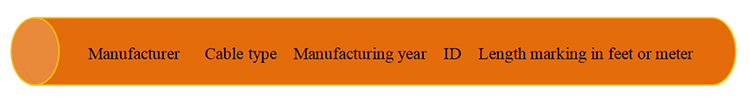

GCYFXTY-XB1.3 (MTE+Cable diameter) |

|

|

MTE 2.8 |

|

Fiber Count |

24 |

|

Thickness |

Nominal value:0.20mm, Average value:0.15mm |

|

Nominal Over Diameter |

2.8±0.1mm |

|

Weight |

7.0 kg/km |

|

Outer Jacket |

HDPE |

|

Cable Fibre Attenuation (Single mode) |

0.34dB/km max@1310nm 0.1995dB/km max@1550nm |

|

Max. Tension Strength |

80N |

|

Max. Crushing force |

600N/100mm |

|

Min. Bending Radius - Static/Dynamic |

10 / 20 outerϕ |

|

Temperature |

Storage -30~50℃; Installation -10~+40℃; Operation -20~+50℃ |

|

Cable Service life (estimate value) |

25 Year |

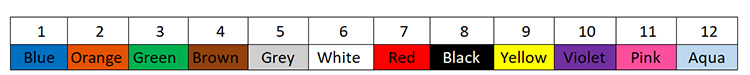

The fibres shall be marked by a coloured coating with 12 different colors following the standard EIA/TIA598 as below :

|

NO |

ITEM |

TEST METHOD |

SPECIFICATION |

|

1 |

Tensile performance IEC60794-1-21-E1 |

-Short-term load:20N

- Time: 5 minute |

Loss change £ 0.10 dB@1550 nm (after test) - Fiber strain £ 0.60 % - No sheath damage |

|

2 |

Crush test IEC60794-1-21-E3 |

- Load: 100 N /100mm - Time: 5 minute - Length: 100 mm |

Loss change £ 0.10 dB@1550 nm (during test) - No sheath damage |

|

3 |

Repeated bending IEC60794-1-21-E6 |

- Bending radius.: 20 × D - Load: 25N - Flexing rate: 2sec/cycle - No. of cycle: 25 |

- No fiber break - No sheath damage |

|

4 |

Water penetration IEC60794-1-22-F5 |

- Height of water: 1m - Sample length: 3 m - Time: 24 hr |

- No drip through the cable core assembly |

|

5 |

Twist IEC60794-1-21-E7 |

- Length: 1 m - Load: 40N - Twist rate: ≤60sec/cycle - Twist angle: ±180° - No. of cycle: 5 |

Loss change £ 0.10 dB@1550 nm (during test) - No sheath damage |

|

6 |

Temperature Cycling IEC60794-1-22-F1 |

- Temperature step: +20oC→-20oC→+70oC→+20oC - Number of cycle: 2 turns - Time per each step: 12 hrs |

- Loss change £ 0.15dB/km@1550 nm (during test) - Loss change £ 0.05dB/km@1550 nm (after test) - No sheath damage |

1. The cables are packed in carton, coiled on Bakelite & Fumigated wooden drum. During transportation, right tools should be used to avoid damaging the package and to handle with ease. Cables should be protected from moisture; kept away from high temperature and fire sparks; protected from over bending and crushing; protected from mechanical stress and damage.

2. Packing length :2000-5000m/reel.