Choosing the right All-Dielectric Self-Supporting (ADSS) cable depends on various factors such as the application, environmental conditions, and specific requirements of the installation. Here are some key considerations to help determine the right type of ADSS cable for your needs:

1. Application and Environment

Span Length: ADSS cables are designed for different span lengths. Short, medium, and long span ADSS cables are available to suit the distance between support points.

Load Requirements: Consider the mechanical loads, such as wind and ice loading, that the cable will need to withstand.

Temperature Range: Ensure the ADSS cable can operate within the temperature range of your installation environment.

2. Cable Design

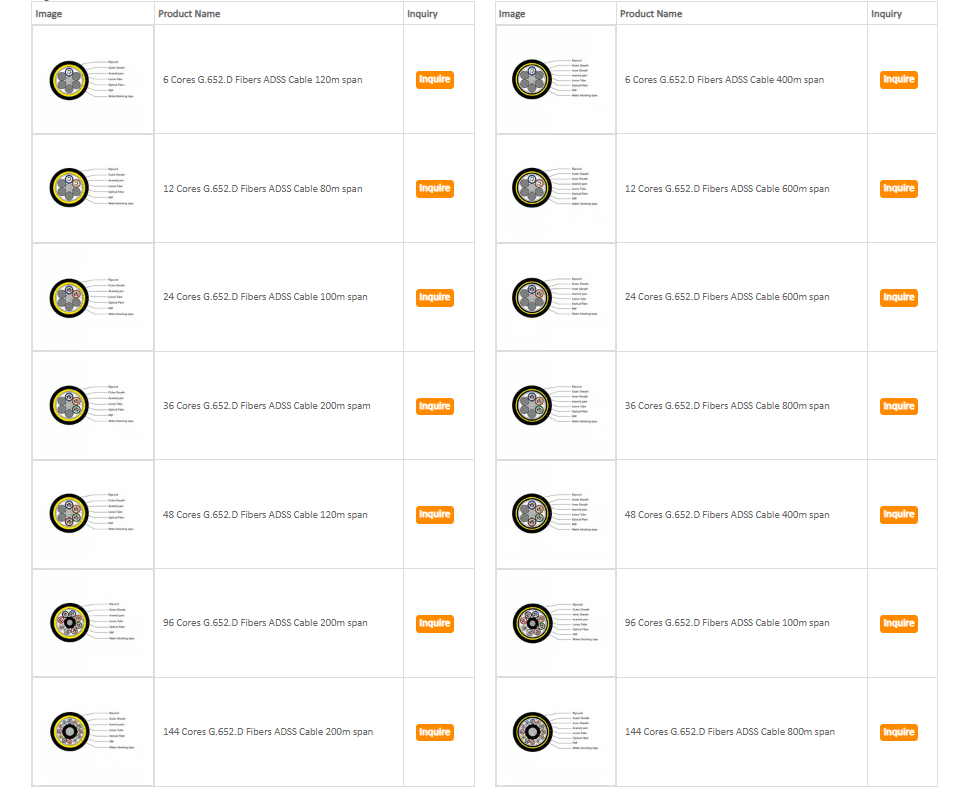

Fiber Count: Choose the fiber count based on your current and future data transmission needs.

ADSS cables come in various fiber counts, typically ranging from a few fibers to several hundred.

Strength Members: ADSS cables have different types of strength members to provide tensile strength. The choice of strength members (e.g., aramid yarns, fiberglass) depends on the required tensile strength and environmental conditions.

3. Installation Considerations

Sag and Tension: Ensure the cable can maintain the appropriate sag and tension within the installation environment to avoid excessive sagging or tensioning.

Installation Methods: Consider the installation methods and tools available.

ADSS cables can be installed using various methods such as direct attachment to poles, lashing to existing infrastructure, or installation on messenger wires.

4. Environmental Conditions

UV Resistance: If the cable will be exposed to direct sunlight, ensure it has UV-resistant properties.

Corrosion Resistance: In coastal or industrial environments, choose cables with materials that resist corrosion.

Electrical Interference: If the installation is near high-voltage power lines, ensure the ADSS cable has the necessary electrical resistance properties.

5. Standards and Regulations

Compliance: Ensure the ADSS fiber cable meets relevant industry standards and regulations for your region and application (e.g., IEEE, ITU, IEC).

Quality and Certification: Choose cables from reputable manufacturers with appropriate quality certifications.

Types of ADSS Cables:

Short Span ADSS Cables: Designed for installations with span lengths typically up to 150 meters. Suitable for urban and suburban areas.

Medium Span ADSS Cables: Suitable for span lengths between 150 to 500 meters. Commonly used in rural areas.

Long Span ADSS Cables: Designed for span lengths exceeding 500 meters. Used in challenging terrains and long-distance applications.

Custom ADSS Cables: Tailored for specific applications with unique requirements, such as high fiber counts or specialized environmental resistance.

Conclusion

To select the right ADSS cable, assess your specific needs in terms of span length, environmental conditions, load requirements, and installation methods. Consulting with a cable manufacturer or supplier can provide additional guidance and ensure you choose the most appropriate ADSS cable for your application.

If you have specific requirements on adss fiber optic cable or accessories, please share more details, and I can offer more tailored advice.

Whatever your goals, GL CABLES can help you determine the cable that best suits your network needs.

To learn more, visit our products center(https://www.gl-cables.com/product.html), or contact us and a representative will reach out directly.