Type tests includes tensile strength test which is considered as one of the most important design type test along with the temperature cycling and water penetration tests. Other tests such as crush resistance, impact, cable bend, twist or torsion, repeated bending and abrasion etc can also be performed as per customer requirement. Some times tensile strength test and water penetration tests are included in routine tests where these tests are conducted on a sampling basis. Some customers demand water penetration test to be conducted as routine test. In this case manufacturer has to conduct water penetration test on all the samples. In some cases, samples from inner end and outer end of the cables shall be tested up on customer demand.

Attenuation test is the most important routine test for a fiber optic cable. Attenuation test are conducted by using OTDR according to IEC 60793-1-40C on finished fiber optic cables in fiber cable manufacturing industry. The equivalent EIA/TIA test method is TIA/EIA-455-61A or FOTP-61. There are some customers who insist to test attenuation on all the fibers in a fiber optic cable using the cut-back method. The IEC test method for cut-back is IEC 60793-1-40A. This test method requires access to both ends of the cable. The inner end of the cable on the drums shall sufficiently be long enough to reach to the spectral attenuation measurement system. The inaccuracy of this test method on finished cables comes when the cables have bad or overlapped winding on drums and sharp bends. This will result in high spectral attenuation. Also there are some customer specifications that demand the test of attenuation using insertion loss technique as per IEC 60793-1-40B. This test method is applicable to short length pigtails and patch cords. Fiber cable supplier has to convince the customer with relevant supporting documents that back scattering method, though not accurate 100%, can be employed to verify attenuation performance of finished cables for sufficiently longer lengths and for routine tests.

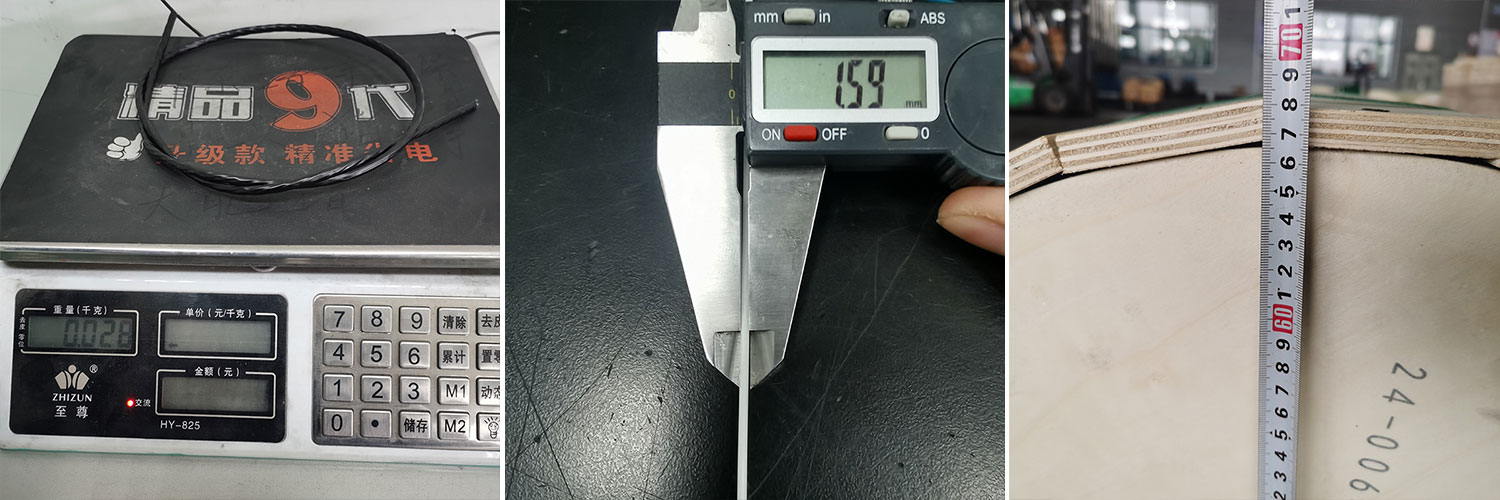

Physical measurements include verification of outer diameter, thickness of sheaths, metallic wrapping layers if any, diameter of central strength member, dimensions of the loose tubes etc. Some customers may ask to test the excess fiber length in finished cable. Visual inspection is carried out to verify the color arrangement of optical fibers and tubes with in the cable. There may be cases of jumped over tubes that change the order and position of the tubes inside the stranded core. If all the loose tubes are color coded, this problem may not create big troubles in the field. If a marker and tracer method is followed in the cable construction and if any of the natural or white color tubes changes their position, it is hard to find out. By connecting the outer end fiber of the each tube one by one to the OTDR, the fibers at the inner end of the cable shall be verified for continuity. This will help to identify the jump-over or cross over of tubes at the middle of the stranding process. If the tube identification is done by marker and tracer method, the jump-over or cross-over of tubes can not be excused since this will create troubles during the splicing in the field.

Routine tests include verification of the sheath markings and printed length accuracy with respect to the actual length. Drum label verification and packing compliance inspection is also part of routine tests on fiber cables.