Fiber optic cables have revolutionized telecommunications, offering high-speed data transmission over long distances with minimal signal loss. But what exactly goes into making these advanced cables? The raw materials used in the construction of fiber optic cables play a crucial role in their performance, durability, and reliability. Here’s a breakdown of the key materials involved:

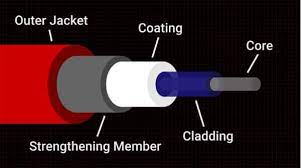

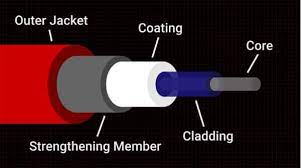

1. Optical Fiber (Core and Cladding)

The most critical raw material in fiber optic cables is the optical fiber itself. Optical fibers consist of two main components: the core and the cladding.

Core: The core is the central part of the fiber, where light travels. It is typically made from ultra-pure silica glass (SiO₂), although plastic cores are used in certain applications. The purity of the glass is essential for minimizing light signal loss (attenuation) over long distances.

Cladding: Surrounding the core is the cladding, which is also made of silica glass but has a lower refractive index. This difference in refractive index between the core and the cladding ensures that light signals remain within the core by reflecting back at the core-cladding boundary. This total internal reflection is key to efficient light transmission.

2. Coating Materials

To protect the delicate optical fibers, they are coated with a protective material. The primary raw material for this coating is acrylate, a type of polymer that is applied in layers to protect the glass fibers from moisture, abrasion, and other environmental hazards.

Primary Coating: This is the first layer of protection around the cladding, typically made from a UV-cured acrylate. It cushions the fiber and protects it from external forces.

Secondary Coating: A second protective layer made of tougher polymer materials, such as polyamide or polyethylene, adds strength and further shields the fiber from mechanical damage.

3. Strengthening Materials

To give fiber optic cables the mechanical strength they need for installation and to protect them from stretching or breaking, strengthening materials are added. These are typically made from:

Aramid Yarn: Commonly known as Kevlar, aramid yarn is a strong, synthetic fiber that provides tensile strength, preventing the optical fibers from being damaged during installation or under tension.

Fiberglass Rods: Sometimes, fiberglass or other reinforcing rods are used to increase the cable's rigidity and prevent bending.

4. Jacket Materials

The outer protective covering, known as the jacket, is made from durable materials that shield the entire cable from environmental factors like water, chemicals, heat, and UV radiation. The primary materials used for jackets include:

Polyethylene (PE): High-density polyethylene (HDPE) is commonly used for outdoor cables due to its toughness, flexibility, and resistance to UV radiation and moisture.

Polyvinyl Chloride (PVC): Often used for indoor cables, PVC offers good flame resistance and flexibility.

Thermoplastic Elastomers (TPE): In some cases, TPE is used for cables that require enhanced flexibility and durability.

5. Water Blocking Materials

For outdoor and underground installations, fiber optic cables are often exposed to moisture, which can damage the fibers. Water-blocking materials are used to protect the fibers from water ingress. These materials include:

Water-Blocking Gels: Applied inside the cable to prevent water from seeping into the core.

Water-Swellable Tapes or Yarns: These materials expand upon contact with water, sealing any gaps and keeping the fibers dry.

6. Ripcords

Ripcords are thin, strong threads made from synthetic materials like nylon or polyester. They are embedded within the cable jacket to make it easier to strip the jacket for installation or maintenance.

Conclusion

The raw materials used in fiber optic cables—ranging from ultra-pure silica glass for the core and cladding, to polymers like polyethylene and aramid yarn for protection and strength—are carefully selected to ensure optimal performance, durability, and environmental resistance. These materials work together to provide the high-speed, reliable data transmission that fiber optic networks are known for, making them an essential component of modern telecommunications infrastructure.