For optical fiber cable manufacturers, production cost is a very critical issue. Only by effectively controlling costs can we maintain competitiveness in the fierce market competition. In this article, GL CABLES as a professional fiber cable company with 20 years manufacturing and export experience, We will introduce some methods and measures to reduce production costs to help fiber cable manufacturers better control costs.

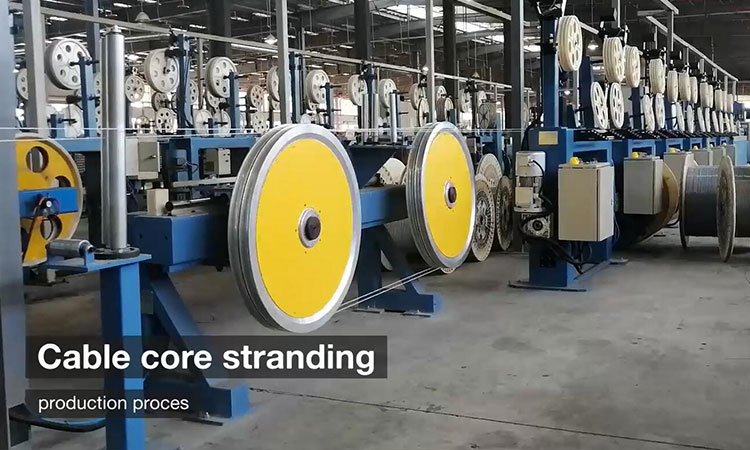

Fiber cable manufacturers can reduce costs by optimizing production processes. Through refined management, reasonable arrangement of production processes, and full use of production equipment and human resources, production efficiency can be effectively improved and production costs can be reduced. At the same time, manufacturers can use some advanced production technologies and automation equipment to reduce manual intervention and improve production efficiency and product quality.

Raw material costs are an important factor affecting the production costs of optical cable manufacturers. In order to control raw material costs, manufacturers can adopt some measures, such as purchasing raw materials through multiple channels, selecting suppliers with reasonable prices and good quality, and implementing effective logistics management. In addition, manufacturers can also optimize raw material inventory to avoid excessive inventory waste.

Energy consumption is an important part of the production cost of fiber optic cable manufacturers. In order to reduce energy consumption, manufacturers can adopt some measures, such as reasonable use of natural light and natural ventilation, installation of energy-saving equipment and intelligent control systems, and implementation of energy management systems. These measures can effectively reduce energy waste and reduce production costs.

Labor costs are an important factor affecting the production costs of fiber optic cable factory. In order to reduce labor costs, manufacturers can adopt some measures, such as implementing a flexible work system, reasonably arranging employee working hours and tasks, and improving employee work efficiency and performance. At the same time, manufacturers can improve employee skills and qualities through training and learning to improve employee work efficiency and reduce production costs.

Improving product quality is an important way to reduce production costs. "quality first, service supreme, mutual benefit" is our business guide, By improving product quality, customer complaints and maintenance costs can be reduced, customer satisfaction can be increased, and product competitiveness can be improved.