Electrical corrosion in ADSS (All-Dielectric Self-Supporting) optical cables is a serious issue that can lead to the degradation and failure of the cable over time. GL FIBER here’s an overview of what it involves:

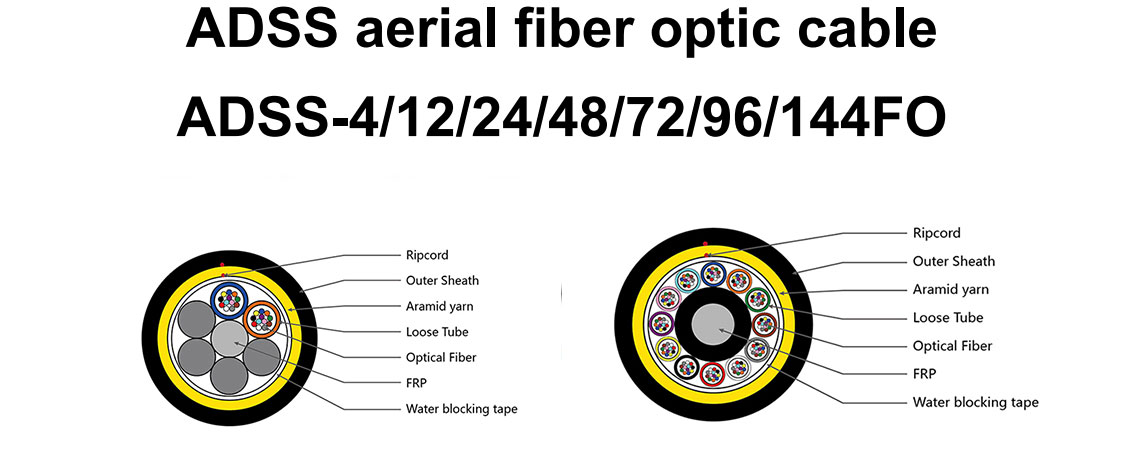

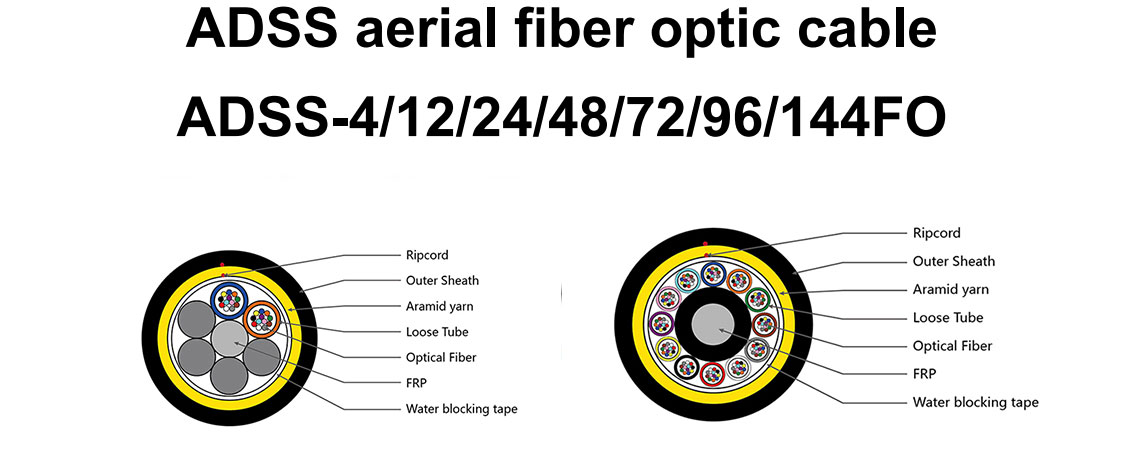

What is ADSS Optical Cable?

ADSS cables are a type of fiber optic cable designed to be self-supporting without any metallic elements. They are used in outdoor installations, often strung between utility poles or towers. Since they are dielectric, they don’t conduct electricity, making them ideal for installations in areas with high electrical interference, such as near power lines.

What is Electrical Corrosion?

Electrical corrosion, in the context of ADSS cables, refers to the degradation of the cable's materials due to electrical and environmental factors. Although the ADSS cable itself is dielectric, it can still be affected by electrical phenomena such as:

Electric Field Stress: When ADSS cables are installed near high-voltage power lines, they can be subjected to intense electric fields. These fields can cause ionization of air molecules near the cable surface, leading to partial discharges. Over time, these discharges can degrade the outer sheath of the cable, leading to cracks and the ingress of moisture.

Electrical Tracking: This occurs when conductive paths form along the surface of the cable, usually due to the accumulation of pollutants and moisture. These conductive paths can cause localized heating, leading to the breakdown of the cable’s materials.

Corrosion from Grounding Issues: In some cases, improper grounding or faults in the electrical system can lead to stray currents, which can cause corrosion even in dielectric materials. This is more common in environments where the cable is exposed to conductive contaminants like salt, industrial pollutants, or acid rain.

Preventing Electrical Corrosion in ADSS Cables

Proper Installation: Ensuring that ADSS cables are installed with the correct tension and in locations that minimize exposure to high electric fields can reduce the risk of corrosion.

Use of Track-Resistant Materials: Modern ADSS cables often use track-resistant outer jackets to minimize the risk of electrical tracking.

Regular Inspection and Maintenance: Periodic inspections can help identify early signs of electrical corrosion, allowing for preventative measures before significant damage occurs.

Appropriate Grounding: Ensuring that the surrounding infrastructure is properly grounded can prevent stray currents that could lead to corrosion.

Conclusion

While ADSS cables are designed to withstand harsh environmental conditions, they are not entirely immune to electrical corrosion. Understanding the causes and implementing preventative measures is key to extending the lifespan of these cables.