With 20 years of experience in professional opitcal cable manufacturing, we have a set of mature methods and experience for optical cable construction.

Outdoor construction of optical cable:

The most important thing for laying

optical cables over long distances is to choose a suitable path. The shortest path is not necessarily the best here. We must also pay attention to the right to use the land, the possibility of erection or burial, etc. There must be a very complete design and construction drawings to facilitate and reliable construction and future inspections. During construction, we must always pay attention to not subject the optical cable to heavy pressure or be stabbed by hard objects.

When the optical cable turns, its turning radius must be greater than 20 times the diameter of the optical cable itself.

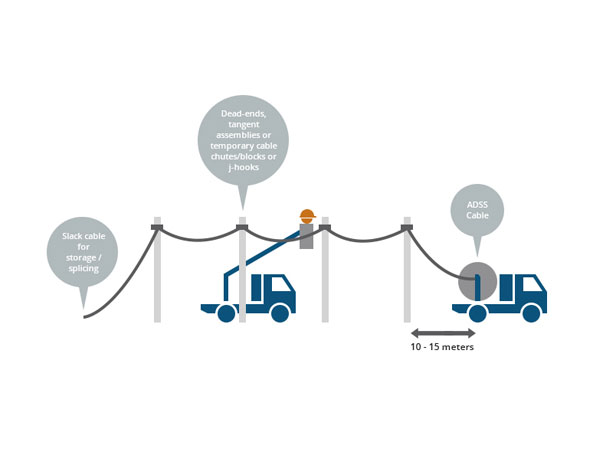

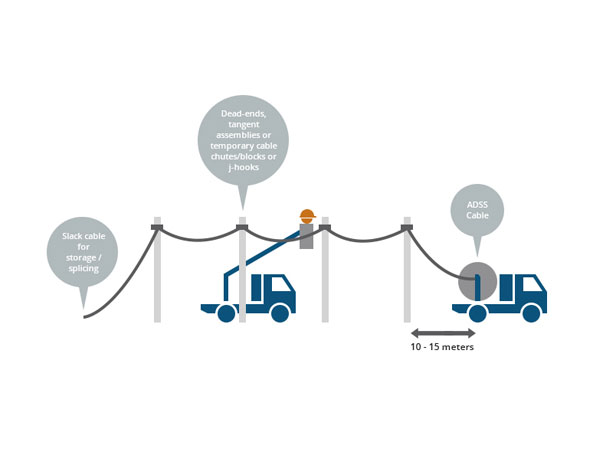

1) Outdoor overhead optical cable construction:

A. Hanging wire support overhead method, this method is simple and cheap, and is the most widely used in my country, but it takes time to add hooks and arrange.

B. Hanging wire winding overhead method, this method is more stable and requires less maintenance. But it requires a special winding machine.

C. Self-supporting overhead method, which has high requirements for line trunks, is difficult to construct and maintain, and has high cost. It is rarely used in China at present.

D. When overhead, a guide device must be added to the optical cable lead-in line trunk, and the optical cable should be prevented from dragging on the ground. Pay attention to reducing friction when pulling the optical cable. A section of optical cable should be left on each trunk for extension and retraction.

E. Pay attention to the reliable grounding of metal objects in the optical cable. Especially in mountainous areas, high-voltage power grid areas and multi-regions, there are generally 3 grounding points per kilometer, and even non-metallic optical cables should be used.

2) Outdoor pipeline/duct optical cable construction:

A. Before construction, the pipeline occupancy should be checked, the plastic sub-tube should be cleaned and placed, and the traction line should be placed at the same time.

B. Calculate the laying length and make sure there is enough reserved length.

C. The laying length should not be too long (generally 2KM) at a time, and the wiring should be pulled from the middle to both sides.

D. The cable pulling force is generally not more than 120kg, and the reinforced core part of the optical cable should be pulled, and the waterproof reinforcement treatment of the optical cable head should be done.

E. A guide device must be added at the introduction and exit of the optical cable, and it cannot be dragged directly on the ground.

F. Pipeline optical cables should also pay attention to reliable grounding.

A. The depth of the direct buried optical cable trench should be excavated according to the standard, the standard is shown in the table below:

B. Where trenches cannot be dug, overhead or drilled pre-buried pipelines can be laid.

C. The bottom of the trench should be kept flat and solid, and a part of sand, cement or support can be pre-filled when necessary.

D. Manual or mechanical traction can be used during laying, but attention should be paid to guidance and lubrication.

E. After laying, the soil should be covered and compacted as soon as possible.

4) Laying of optical cables in buildings:

A. When laying vertically, special attention should be paid to the load-bearing problem of optical cables. Generally, the optical cables should be fixed once every two floors.

B. When the optical cable passes through the wall or floor, a protective plastic tube with a guard should be added, and the tube should be filled with flame-retardant fillers.

C. A certain amount of plastic pipes can also be pre-laid in the building, and the optical cable can be laid by traction or vacuum method when the optical cable is to be laid later.