Installing underground fiber optic cable is critical in establishing high-speed internet infrastructure. Unlike traditional copper cables, fiber optic cables require specific handling and techniques during installation. This guide delves into the meticulous installation of underground fiber optic cable, ensuring optimal performance and longevity.

How To Install Underground Fiber Optic Cables?

Fiber Optic Internet

1. Planning & Designing the Network

Before any physical work begins, it’s crucial to design the network layout. This stage involves determining where the fiber optic cable will enter the system, calculating the cable’s minimum bend radius to avoid damage, and planning the path of the cable pull.

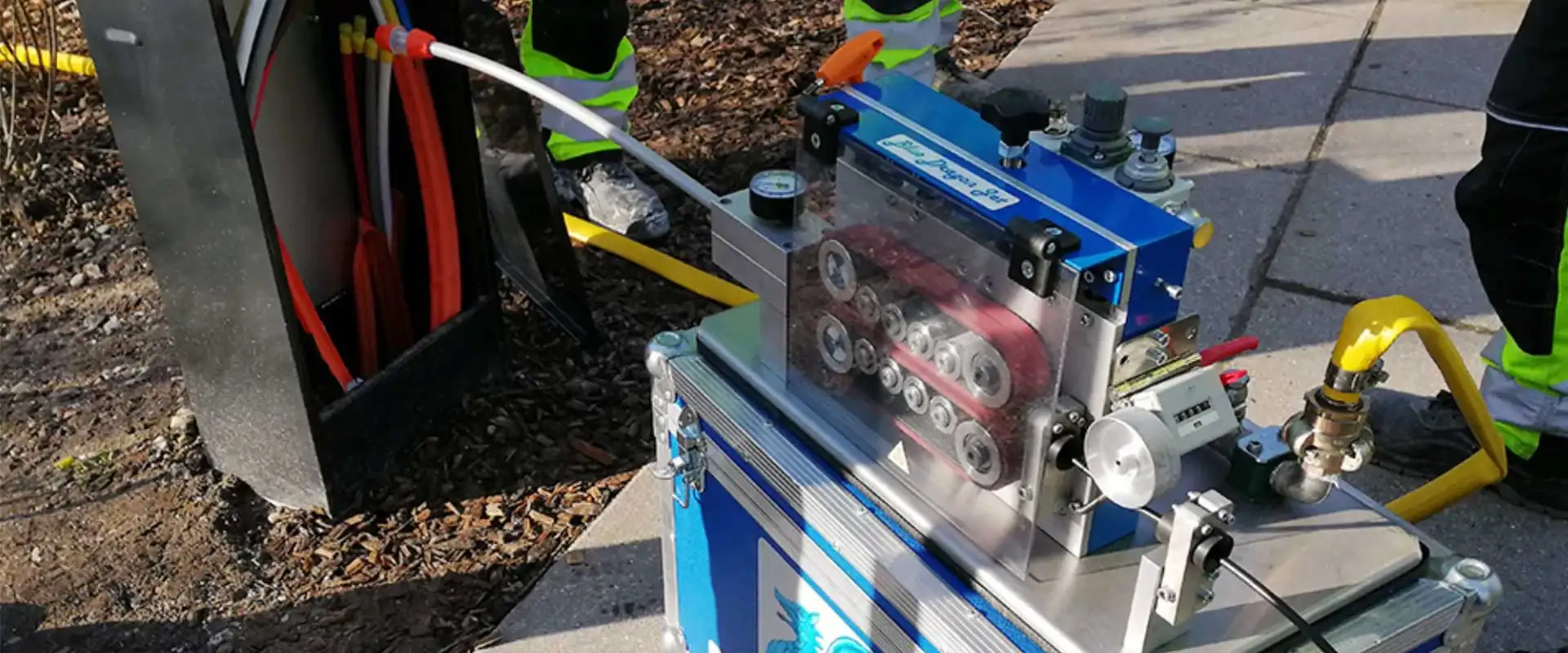

Using the right pulling equipment is essential to manage the delicate nature of fiber cables.

2. Trenching & Conduit Placement

-

Trenching Process & Techniques: The trenching process for laying underground cable involves excavating a path for the conduit to house the fiber cable. Techniques vary based on soil type [1] and the depth required, with particular attention to avoid disturbing existing underground utilities like the power cable.

-

Conduit Placement Strategies: Conduits are laid to protect the fiber optic cables after trenching. Conduits must be robust enough to protect the cables from environmental factors and potential physical damage.

-

Depth & Soil Type Considerations: The depth at which the conduit is laid depends on the soil type and local regulations. Ensuring the conduit is deep enough to protect the cables from surface activities and environmental elements is crucial.

3. Cable Laying & Protection

-

The process of laying fiber optic cables requires meticulous handling, mainly when cables are buried underground. Care must be taken during cable pulling to avoid sharp bends that could damage the fiber, especially with loose tube cables.

-

Pulling tension is closely monitored using pulling tape and a pulling grip.

-

In some cases, plowing equipment is used for direct burial. In this most common practice, fiber optic cable can be buried directly in the ground without conduit as long as the cable’s design includes protective metallic components.

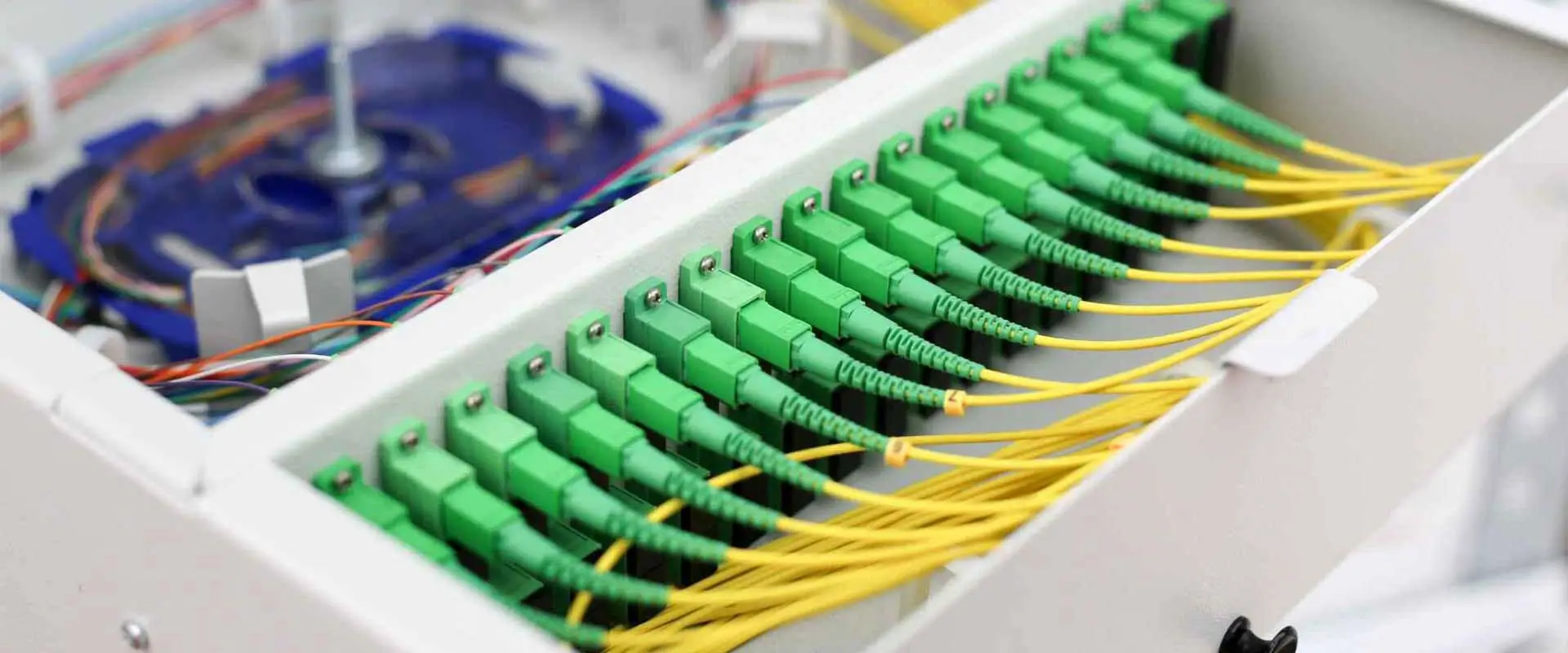

4. Splicing, Termination & Conduit Utilization

Once laid, fiber optic cables require splicing and termination. Fusion splicer is the most common method used for fiber splicing, ensuring precise alignment and data transmission efficiency. The installation process also involves strategically utilizing conduits to protect the buffer tube and the cable from environmental factors. This step is crucial in maintaining the integrity of the cable placement over time.

5. Testing & Verification

After the installation process, rigorous testing and verification are essential. It ensures that fiber optic cable enters the network correctly and functions optimally.

Testing checks for faults along the cable length and verifies the network’s overall performance. This final step is critical to ensure the reliability and efficiency of the network for high-speed data transmission.

Challenges & Solutions in Fiber Optic Installation

-

Installing Fiber Optic Internet

-

Underground fiber optic installation comes with its challenges while providing numerous benefits. Addressing these is key to a successful installation.

Common Challenges in Underground Installation

1. Location Accessibility: Accessing the location where the fiber optic cable is to be installed can be challenging, especially in densely populated or geographically complex areas.

2. Trench and Duct Work: Digging trenches and installing ducts in certain terrains can be difficult. Determining the best route for the trench and the type of duct work needed is essential.

3. Connecting and Pulling Cables: The operation of pulling the cables through ducts requires precision. There’s a risk of damaging fibers if the cabling is pulled with too much force or without proper guidance.

4. Storage and Splice Access: Managing the storage and access for splice locations is often complex. Each splice point needs to be easily accessible for future maintenance or repairs.