GL FIBER's aerial fiber optic cables main include metallic Fig 8 range for harsh long distance robust network. Aerial Fiber cable delivers a dependable solutions for all weather conditions via faster mode of installation. aerial cables are specifically designed for easy and economical installation where metallic messengers can’t be used like power lines, street furniture.

In the quest to expand high-speed internet and telecommunications networks, aerial fiber optic cables have become a cornerstone of modern connectivity solutions. Designed for installation above ground—often suspended between poles, towers, or along existing utility lines—these cables offer a cost-effective and efficient way to deploy fiber optics in both urban and rural landscapes. This article delves into the design, advantages, and applications of aerial fiber optic cables, showcasing their pivotal role in bridging the digital divide.

What Are Aerial Fiber Optic Cables?

Aerial fiber optic cables are optical cables specifically engineered for outdoor overhead installation. Unlike underground cables, which require trenching, aerial cables are mounted on elevated structures, leveraging existing infrastructure to minimize deployment time and costs. They are built to endure environmental stressors such as wind, temperature fluctuations, UV exposure, and ice loads while maintaining reliable data transmission.

Key Design Features

Aerial cables incorporate unique structural elements to ensure durability and performance in exposed environments:

Optical Fiber Core:

Available in wide range of 1F-432F, in both single-mode and multi-mode fibre variants

Strength Members:

To withstand tension and mechanical stress, aerial cables integrate robust strength components such as dielectric glass-reinforced plastic (GRP) rods, aramid yarn, or steel wires. These materials provide tensile strength without adding excessive weight.

Weather-Resistant Jacket:

The outer jacket is made from high-density polyethylene (HDPE) or UV-stabilized polyethylene to resist moisture, sunlight, and temperature extremes. Some designs include a corrugated steel tape or aluminum barrier for additional protection against rodents or accidental impacts.

Self-Supporting vs. Lashed Cables:

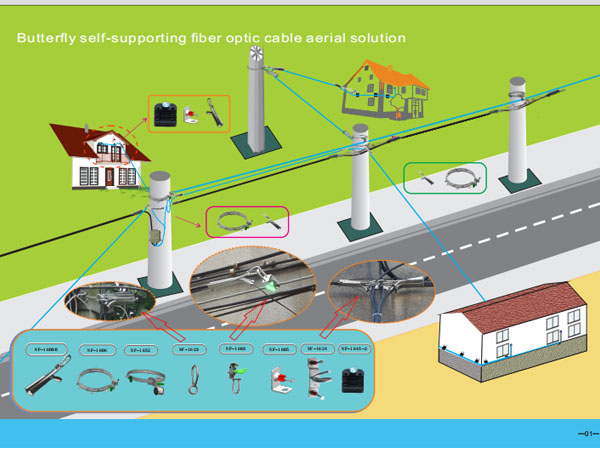

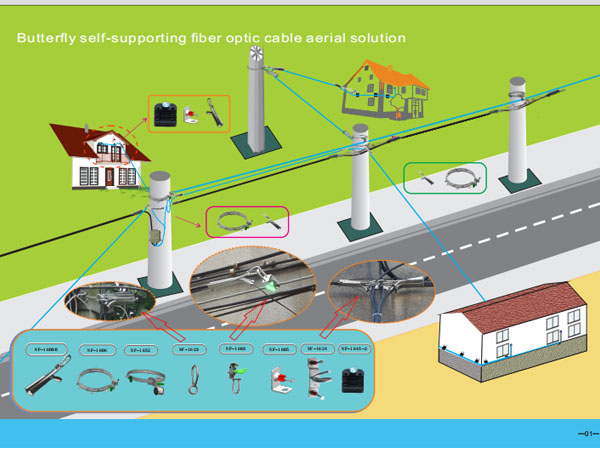

Self-Supporting cables (e.g., ADSS—All-Dielectric Self-Supporting) have built-in strength members, allowing them to hang independently without external support wires.

Lashed cables are attached to a separate messenger wire (e.g., steel or GRP) that bears the mechanical load.

Advantages of Aerial Fiber Optic Cables

Cost-Effective Deployment:

Aerial installation avoids the high costs of trenching, making it ideal for rural or remote areas, river crossings, and mountainous terrains.

Rapid Installation:

Leveraging existing utility poles or towers accelerates deployment, enabling faster network expansion for 5G, FTTH (Fiber-to-the-Home), or emergency communications.

Environmental Adaptability:

UV-resistant jackets and waterproof designs ensure long-term performance in harsh weather, from scorching heat to freezing conditions.

Minimal Ground Disruption:

Overhead installation preserves landscapes, reduces permitting challenges, and avoids conflicts with underground utilities.

Scalability:

Aerial networks can be easily expanded or upgraded by adding new cables to existing routes.

Common Applications

1. Long/Medium/Short span aerial installations

2. Last mile communication system

3. Installation with high voltage power lines (ADSS)

4. Subscriber network system

Installation Considerations

Span Length: The distance between poles must align with the cable’s tensile strength to prevent sagging or breakage.

Wind and Ice Loads: Engineers must calculate regional weather risks to select cables with adequate durability.

Clearance Regulations: Compliance with safety standards (e.g., distance from power lines) is critical.

Maintenance Access: Aerial cables should be routable for inspection and repairs without disrupting traffic or utilities.

Choosing the Right Aerial Cable

Selecting an aerial fiber optic cable depends on:

Environment: Harsh climates may require armored jackets or anti-rodent layers.

Span Requirements: Self-supporting cables suit shorter spans, while lashed designs are better for long distances.

Electrical Safety: Dielectric (non-metallic) cables like ADSS are essential near high-voltage power lines.

Standards Compliance: Certifications such as IEC 60794-3-20 or ANSI/ICEA S-87-640 ensure quality and safety.

Conclusion

Aerial fiber optic cables are a linchpin of global connectivity, offering a versatile and economical solution for expanding high-speed networks across diverse terrains. Their resilience to environmental challenges, coupled with rapid deployment capabilities, makes them indispensable for bridging urban-rural digital gaps, enhancing mobile communications, and building future-ready infrastructures. As demand for bandwidth surges, aerial fiber optics will continue to play a vital role in connecting communities and powering the technologies of tomorrow—securely, efficiently, and from above.