The MDPE/HDPE 12, 24, 48, 96 Core

ADSS Fiber Cables with Kevlar. Designed for high-performance overhead installations, these cables are built to deliver exceptional durability and reliability, especially in challenging environments.

The ADSS cables feature a Medium-Density Polyethylene (MDPE) or High-Density Polyethylene (HDPE) outer sheath, which provides superior protection against harsh environmental conditions, such as UV exposure, moisture, and extreme temperatures. The use of Kevlar reinforcement adds an extra layer of strength, enabling the cables to handle greater mechanical stresses, making them ideal for long spans and rugged terrains.

DETAIL INFORMATION:

Application: Outdoor Aerial

Fiber Counts: 2-144cores

Span: 50m 120m /200 M Or Customized

Fiber Per Tube: 4/6/8/12/F

Free Sample: Yes

Strength Number: FRP, Kevlar Aramid Yarn

Structure: Stranded Loose Tube

Jacket Color: Black Yellow Bule Or Customized

Operating Temperature: -40℃ To +70℃

Fiber Type: G652D, OM1, G655, OM4, OM5

Jacket Material: AT, PE, MDPE, HDPE, LSZH, TPU

Key features include:

Core Options (12, 24, 48, 96): Flexible configurations for diverse data and bandwidth requirements, suitable for various applications in telecommunication and power distribution networks.

Kevlar Strength Member: Kevlar fibers significantly increase the cable's tensile strength, allowing it to withstand environmental stresses such as wind and ice loading while maintaining its self-supporting capability.

All-Dielectric Design: With no metal components, the ADSS cable is immune to electrical interference, making it perfect for installations near high-voltage power lines.

MDPE/HDPE Sheath: These materials ensure long-term UV and weather resistance, extending the cable’s lifespan even in the harshest conditions.

This ADSS fiber cables solution is ideal for power utility companies, telecommunications networks, and other industries that require robust, long-lasting fiber connectivity across varying terrains.

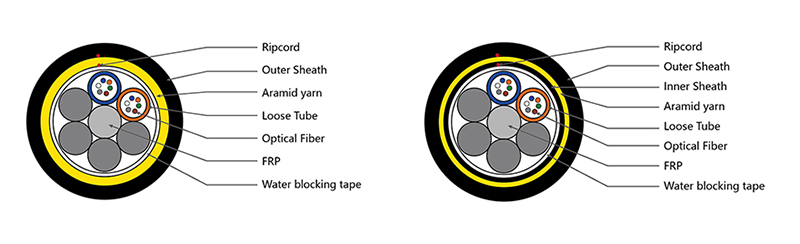

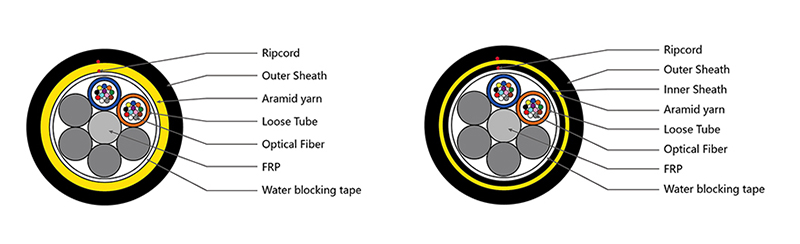

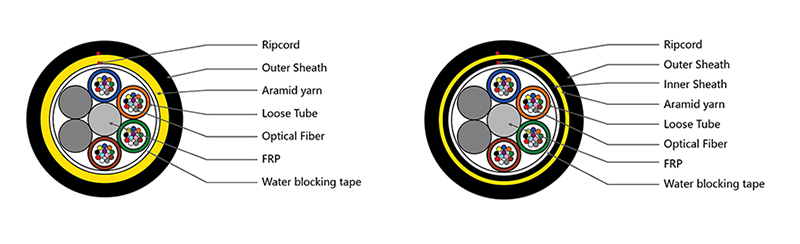

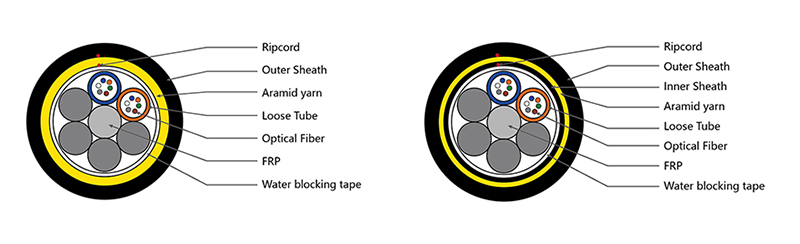

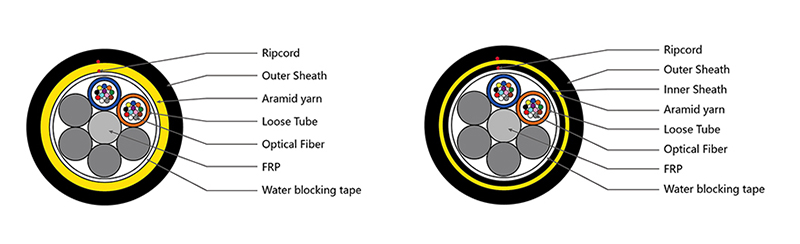

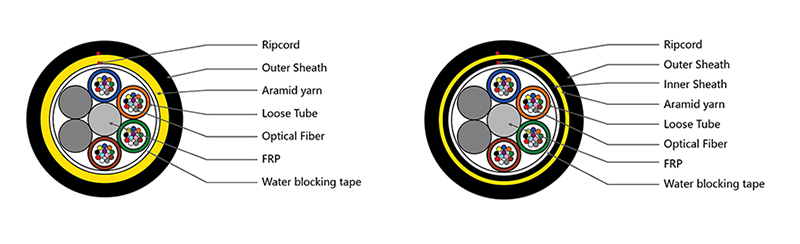

Cable Section:

Standards:

ADSS cable complies with Standard IEEE P 1222 as well as IEC 60794-1.

Structure and Technical Specifications:

ADSS single jacket

|

fiber count

|

structure

|

fiber per tube

|

losse tube diameter

(MM)

|

FRP/pad diameter (mm)

|

Thickness of outer jacket(mm)

|

Ref. Outer

Diameter

(mm)

|

Ref. Weight

(kg/km)

|

|

PE Jacket

|

AT Jacket

|

|

4

|

1+5

|

4

|

1.9

|

2.0/2.0

|

1.7±0.1

|

9.8

|

80

|

90

|

|

6

|

1+5

|

6

|

1.9

|

2.0/2.0

|

1.7±0.1

|

9.8

|

80

|

90

|

|

8

|

1+5

|

4

|

1.9

|

2.0/2.0

|

1.7±0.1

|

9.8

|

80

|

90

|

|

12

|

1+5

|

6

|

1.9

|

2.0/2.0

|

1.7±0.1

|

9.8

|

80

|

90

|

|

24

|

1+5

|

6

|

2.0

|

2.0/2.0

|

1.7±0.1

|

9.8

|

85

|

95

|

|

48

|

1+5

|

12

|

2.0

|

2.0/2.0

|

1.7±0.1

|

10.0

|

88

|

98

|

|

72

|

1+6

|

12

|

2.2

|

2.0/2.0

|

1.7±0.1

|

10.5

|

98

|

108

|

|

96

|

1+8

|

12

|

2.2

|

2.0/3.4

|

1.7±0.1

|

12.0

|

122

|

135

|

|

144

|

1+12

|

12

|

2.2

|

3.0/7.2

|

1.7±0.1

|

15.2

|

176

|

189

|

Tips: all the specifications in the abolve table is approximate data, for more detals specifications, pls contact our sales team via email: sales@gl-fibercable.com;