During operation, the ADSS optical cable, which is under tension, is in a strong electromagnetic field in the space around the conductor. The capacitive coupling between the optical cable and the conductor and the earth puts it in a position of spatial potential. Under the action of spatial potential, the damp or dirty (inevitable) surface of the optical cable generates a ground leakage current to the grounded hardware and generates heat. The heat evaporates the moisture on the surface of the optical cable, randomly (uncontrollably) forming a dry belt, blocking the surface leakage current. When the potential at both ends of the dry belt is high enough, discharge occurs to form an arc (called "dry belt arc"). The basic condition for the occurrence of electrical corrosion is to have a certain leakage current and a sufficiently high spatial potential.

Ground leakage current:

According to data from the west coast of Hanterstor in Scotland: No arc occurs when the ground leakage current is less than 0.3mA. Therefore, 0.3mA is generally recognized as the threshold value for no arcing; when the ground leakage current exceeds the threshold of about 0.5mA, an arc will be generated; as the ground leakage current exceeds 1mA, the arc will become serious; but when the ground leakage current is larger (about more than 5mA), the arc activity will stop, that is, the large current will not generate an arc. The test results also show that the degree of electrical corrosion is related to the tension of the

optical cable.

Standards for optical cables to withstand spatial potential:

According to the relevant standards and specifications, the spatial potential that the outer sheath of ADSS optical cables can withstand is divided into two levels.

Grade A: PE sheath ≤12KV;

Grade B: AT sheath ≥12KV; The upper limit of the B-level sheath is not specified in the relevant standards and specifications, and the usual reference is 20-25KV.

Active length:

The ground leakage current is driven by the spatial potential. At a certain span of the transmission line, assuming that the distance between the optical cable and the conductor remains unchanged (the sag is consistent) and the distance between the optical cable and the earth remains unchanged (in fact, it is impossible and only an assumption), the distance between each point on the surface of the optical cable and the end of the grounded hardware varies greatly. Although the induced voltage in the center of the span is very high, the charging constant is very large, the charging current is extremely small, and there is no leakage current on the surface of the optical cable; as it approaches the end of the hardware installed on the tower, the induced voltage tends to zero sharply and the ground leakage current increases. At the end of the grounded hardware, the ground leakage current reaches the maximum value. If the arcing conditions are met, electrical corrosion occurs. The distance from a certain point where the ground leakage current begins to increase to the end of the hardware is called the "active length", which is the most dangerous area for electrical corrosion. Therefore, there are two active lengths in one span.

Influence of double-circuit phase:

The spatial potential at the optical cable suspension point is affected by the phase arrangement of the three-phase conductors. The phase change of the single circuit has almost no effect, and the phase change of the double circuit conductor has a great influence. In a double-circuit system, as for the installation "space" of ADSS, the ABC-ABC phase is the smallest, and the other phases are expanded to varying degrees, especially the ABC-CBA phase "space" is the largest. For a certain suspension point: the double-circuit line is more complicated when one side is out of power and the single-circuit operation is more complicated, and the space potential may become smaller or larger. Other influences In addition to the phase effect, when the suspension point of a certain optical cable is certain, its space potential will also be affected by the diameter of the conductor and the ground wire, the splitting of the conductor, the wind swing of the hardware and the optical cable, etc.

Control of electrical corrosion:

As far as we know, all electrical corrosion faults occur in the "active length" area, so the range to be controlled is also concentrated in the active length interval.

Static control:

Under static conditions, the space potential of the hanging point of AT sheathed ADSS optical cable working in the 220KV system should be controlled at no more than 20KV (lower for double-circuit and multi-circuit co-racked lines); the space potential of the hanging point of PE sheathed ADSS optical cable working in the 110KV and below system should be controlled at no more than 8KV. The space potential design of the static hanging point should take into account:

(1) System voltage and phase arrangement (double-circuit and multi-circuit are very important).

(2) Tower shape (including tower head and call height).

(3) Length of insulator string (its length varies according to the pollution migration level).

(4) Diameter of conductor/ground wire and splitting of conductor.

(5) Safety limit distance from conductor, ground and crossing objects.

(6) Control of tension/sag/span (under windless, ice-free and annual average temperature conditions, its load is no more than ES of the optical cable, i.e. 25%RTS; under design meteorological conditions, its load is no more than MAT of the optical cable, i.e. 40%RTS).

(7) Jumpers (tension towers) and grounding bodies (such as cement poles) should be studied and their impacts should be considered.

Dynamic control:

Under dynamic conditions, the space potential of the hanging point of AT sheathed ADSS optical cables working in 220KV systems should be controlled at no more than 25KV; the space potential of the hanging point of PE sheathed ADSS optical cables working in 110KV and below systems should be controlled at no more than 12KV. Dynamic conditions should at least take into account:

(1) The system voltage is the nominal voltage. In some cases, there will be an error of +/- (10-15)%, and the positive tolerance is taken;

(2) Wind swing of hardware strings (mainly suspension strings) and optical cables;

(3) The possibility of original phase transposition;

(4) The possibility of single-circuit operation of a dual-circuit system;

(5) The actual situation of pollution migration in the local area;

(6) Possible new crossing lines and objects;

(7) Municipal construction and development plan status along the line (possibly raising the ground);

(8) Other situations that may affect the optical cable.

The electrical corrosion of the

ADSS cable sheath under tension during operation is caused by the ground leakage current and dry strip arc of approximately 0.5-5mA caused by the space potential (or electric field strength) coupled by capacitance. If measures are taken to control the ground leakage current below 0.3mA and no continuous arc is formed, the electrical corrosion of the sheath will not occur in principle. At present, the most practical and effective method is still to control the tension and space potential of the optical cable. The static space potential design of AT or PE sheathed ADSS optical cable should be no more than 20KV or 8KV respectively, and should be no more than 25KV or 12KV respectively under the worst dynamic conditions. The optical cable can be operated safely. The anti-vibration whip in the system with a static space potential of 20KV (mostly 220KV system) or 8KV (mostly 110KV system) is not less than (1-3)m or 0.5m from the end of the twisted wire of the metal fitting, which is one of the effective measures to improve the electrical corrosion of ADSS optical cable. At the same time, the vibration damage of ADSS optical cables and other anti-vibration methods (such as applicable anti-vibration hammers) should be studied.

The installation position of the optical cable (often called the "hanging point") cannot be simply determined by experience based on the system voltage level and/or the distance from the phase conductor. The spatial potential of the hanging point should be calculated according to the specific conditions of each tower type. Although ADSS optical cable electrical corrosion failures have occurred repeatedly in recent years, a large number of practices have proved that ADSS optical cables can continue to be promoted and applied in 110KV systems; ADSS optical cables used in 220KV systems can also continue to be promoted and applied after fully considering static and dynamic working conditions. Under the premise of ensuring the quality of ADSS optical cables, standardizing engineering design, construction and operating conditions, the electrical corrosion of ADSS optical cables can be controlled. It is recommended to formulate and implement relevant specifications/procedures as soon as possible.

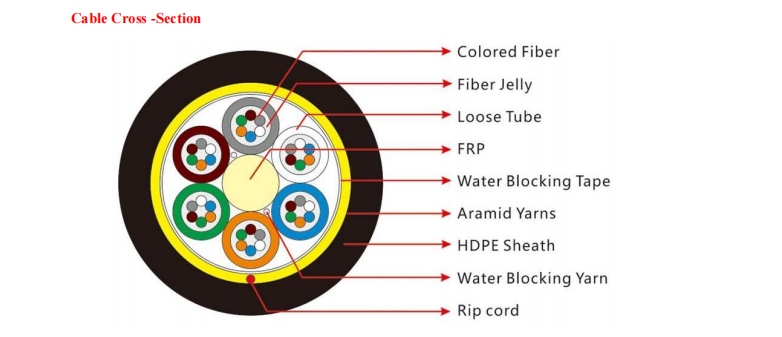

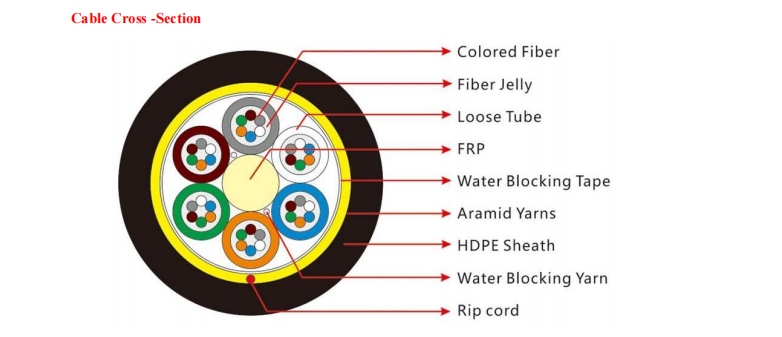

GL FIBER' ADSS power optical cable main features:

1.Non-metallic structure, good insulation performance, lightning protection

2.Excellent production technology, imported aramid yarn with uniform force, excellent stress-strain performance

3.Optional PE/AT sheath, best anti-electrical corrosion performance; can adapt to harsh climatic conditions, ice coverage can reach 10MM. The distance of 50-1000 meters can be customized according to customer requirements.

If you are interested in our ADSS Cable or accessories, pls kindly contact with our sales or technical team, we will reply you within 12 hours. Email: sales@gl-fibercable.som. Whatsapp: +86 18508406369.