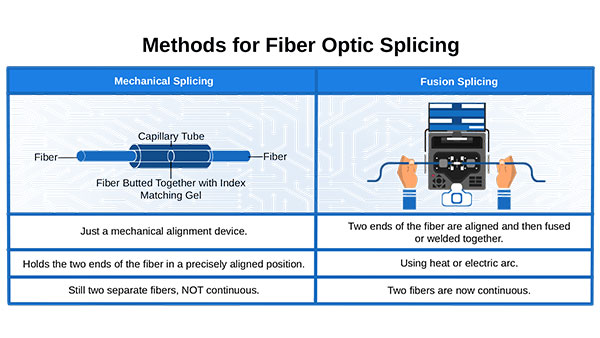

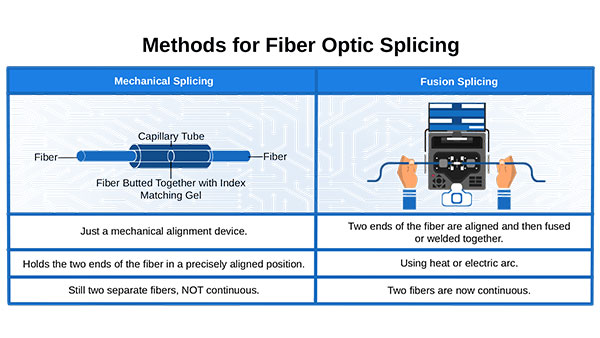

Splicing fiber optic cables involves joining two optical fibers end-to-end to create a continuous optical path. This is typically done using two main methods: fusion splicing and mechanical splicing. Here, GL Fiber will tell you how each method works:

Fusion Splicing

Fusion splicing is the most common method and involves the following steps:

Preparation:

Stripping: Remove the protective coatings, buffer tubes, and jackets from the fiber ends to expose the bare fibers.

Cleaning: Clean the stripped fibers with alcohol wipes to remove any debris or contaminants.

Cleaving: Use a precision cleaver to cut the fibers at a precise 90-degree angle to ensure a smooth, flat end face.

Splicing:

Alignment: Place the cleaved fibers into the splicing machine, which uses cameras and motors to align the fiber ends with high precision.

Fusion: The splicing machine generates an electric arc to fuse the fiber ends together, melting and joining them to form a continuous optical path.

Inspection: The splice is inspected using the machine’s built-in microscope or a separate inspection device to ensure proper alignment and quality.

Protection:

Splice Protection Sleeve: Place a protective sleeve over the splice to shield it from mechanical damage and environmental factors.

Heat Shrink: Use a heat shrink oven or heat gun to shrink the protective sleeve, securing it around the splice.

Mechanical Splicing

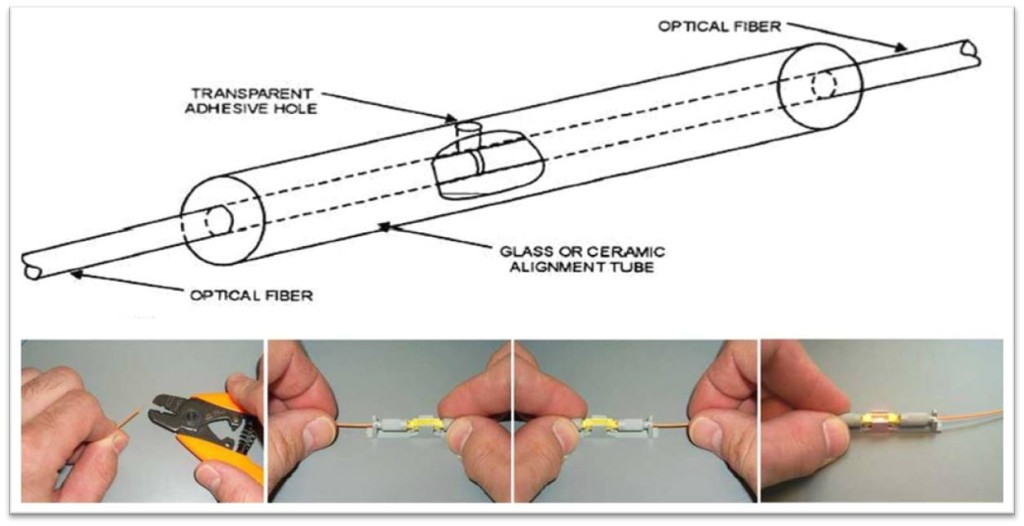

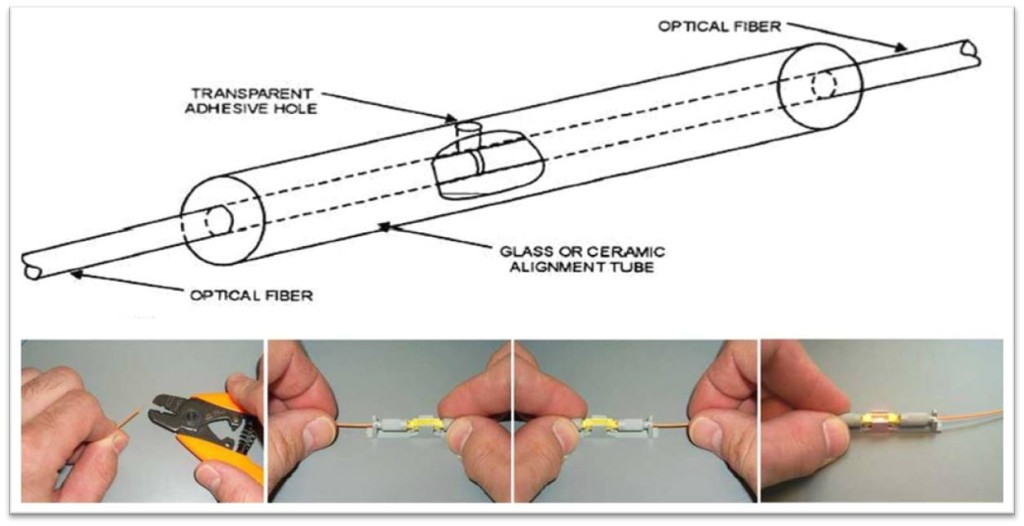

Mechanical splicing involves physically aligning and holding the fiber ends together within a special housing:

Preparation:

Stripping: Similar to fusion splicing, remove the protective coatings to expose the bare fibers.

Cleaning: Clean the stripped fibers with alcohol wipes.

Cleaving: Use a precision cleaver to cut the fibers at a precise 90-degree angle.

Splicing:

Alignment: Place the cleaved fibers into a mechanical splice housing that aligns and holds the fiber ends in place. The housing contains a gel or adhesive to maintain proper alignment and reduce signal loss.

Securing: Close the housing to secure the fibers in place, ensuring they remain aligned.

Protection:

Mechanical Splice Protectors: These protect the splice from environmental factors and mechanical stress. The protectors can vary in design but usually involve some form of clamping or housing.

Comparison

Fusion Splicing:

Pros: Provides a lower loss and more permanent splice with better long-term performance.

Cons: Requires more expensive equipment and skilled technicians.

Mechanical Splicing:

Pros: Faster and easier to perform, with less expensive equipment.

Cons: Generally results in higher loss and may be less reliable over time.

Both methods are used depending on the specific requirements of the fiber optic network, such as the required performance, budget, and available equipment.