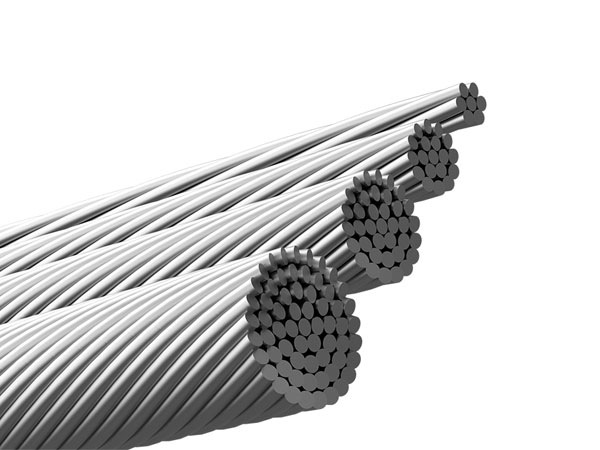

When choosing overhead bare conductors for power transmission, AAAC (All Aluminum Alloy Conductor) and ACSR (Aluminum Conductor Steel Reinforced) are two of the most common options. Understanding their differences helps in selecting the right conductor for your project.

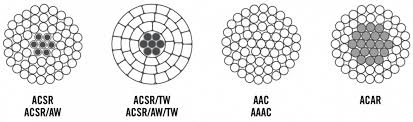

1. Construction & Material

AAAC Conductor: Made entirely of high-strength aluminum alloy, offering excellent corrosion resistance and lightweight properties.

ACSR Conductor: Composed of aluminum strands surrounding a steel core (Aluminum Conductor Steel Reinforced), providing superior mechanical strength.

2. Strength & Load Capacity

AAAC: Lighter but has lower tensile strength compared to ACSR. Ideal for medium-span installations.

ACSR: The steel core enhances strength, making it suitable for long-span and high-tension applications.

3. Corrosion Resistance

AAAC: Performs better in coastal or high-humidity environments due to its all-aluminum alloy construction.

ACSR: The steel core may corrode over time unless galvanized or treated.

4. Electrical Conductivity

AAAC: Slightly better conductivity due to pure aluminum alloy.

ACSR: Conductivity depends on the aluminum portion, but the steel core does not contribute to current carrying capacity.

5. Cost & Applications

AAAC: More cost-effective where corrosion resistance is critical (e.g., coastal power lines).

ACSR: Preferred for high mechanical strength needs (e.g., river crossings, mountainous areas).

Why Choose Us as Your ACSR Conductor Manufacturer?

As a leading ACSR conductor manufacturer with 21+ years of experience, we provide:

✔ ISO-certified production

✔ Custom sizes & configurations

✔ Competitive factory-direct pricing

✔ Rigorous testing & international standards compliance

Whether you need AAAC or

ACSR conductors, we offer reliable solutions tailored to your project. Contact us today for a quote!