The method of laying optical cables on poles is called overhead/aeial laying, as shown in the figure. It is mainly used in areas with small capacity, unstable geology, urban areas where direct burial is not possible and there are no telecommunication pipelines, mountainous areas and areas with special water network conditions and areas where poles are available. Compared with direct underground burial, overhead laying of optical cable is easily affected by external conditions (such as natural climate and human factors), but it is simple to install, easy to maintain, and has low construction costs.

This structure is supported by hanging or bundling (winding) the poles.

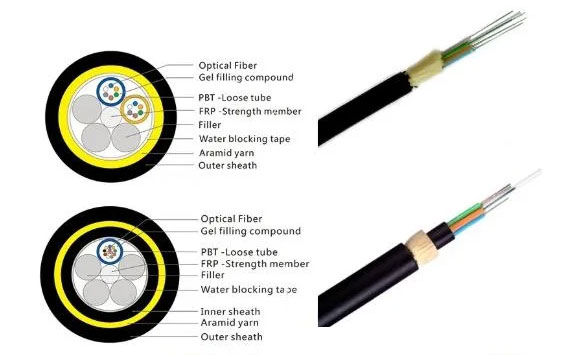

such as earthquake resistance, resistance to tension caused by changes in meteorological loads such as wind, snow, and low temperature, and moisture-proof and waterproof properties. Generally, it can be decided whether to use oil-filled optical cables according to the nature of the line and the environment, but there should be a moisture-proof layer (aluminum foil layer).

The distance in suburban areas varies with different meteorological load zones, with a minimum of 25m and a maximum of 67m. The division of load zones in my country is based on three factors: wind force, ice and temperature. See the table for details.

The strength of the poles and other requirements should meet the construction standards for overhead communication lines.

The safety factor of the suspension wire should not be less than 3 (S≥3). For long-distance primary trunk lines that require overhead laying, when the weight of the optical cable exceeds 1.5kg/m, the distance between poles can be reduced or 7/2.6mm steel strands can be used in heavy load areas.

Aerial laying is not suitable in areas below -30℃.