Fiber optic cables are sensitive to excessive pulling, bending, twisting, crushing and other impact forces, which may alter the fiber property and may pose threats to its performance. Therefore, optical cable should be stored and handled in an appropriate way.

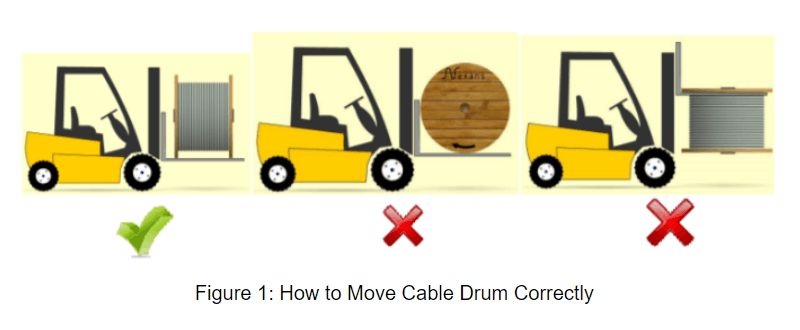

Before Storage: How to Move Cable Drum Correctly

Before storing an optical fiber, it is important to transport or move it correctly because many optical fibers are heavy. Cable drum movement is one of the common ways for fiber transportation. When the cable drum/reel is too heavy to lift manually, it must be moved upright by lifting the cable with a forklift or reel mover. Never drop a cable reel from any height during transportation or use. When unloading from a vehicle, use either the tail-lift/elevator (if fitted) or a suitable mechanical aid such as a forklift truck. Never let reels drop from the vehicle to the ground.

When moving or handling the drum by a forklift, one should operate it in a proper manner to avoid any damage to fiber optic cable. The fork should not have any direct contact with the cable jacket.

Some drums may be of sufficient length and weight to require cranes to load and unload from transport vehicles. Under such circumstances, a spreader bar of sufficient length is necessary to keep the drum flanges from being compressed by the lifting chains.

Where Should Fiber Optic Cable Be Stored?

In no circumstances shall any cable boxes or reels be stored outside or in a harsh environment. Instead, these cables should be stored in a dry and UV-protected location, such as a room or container. Choose a site for storage with no risk of excessive humidity, falling objects, chemical spills (oil, grease, etc.), open flames, or excessive heat. Elements like moisture and other contamination should also be considered when picking storage locations.

Note: Although the cables can be stored out of doors, the appearance of the reel can suffer weathering or other damages due to the changeable weather. Therefore, storing all reels indoors is recommended.