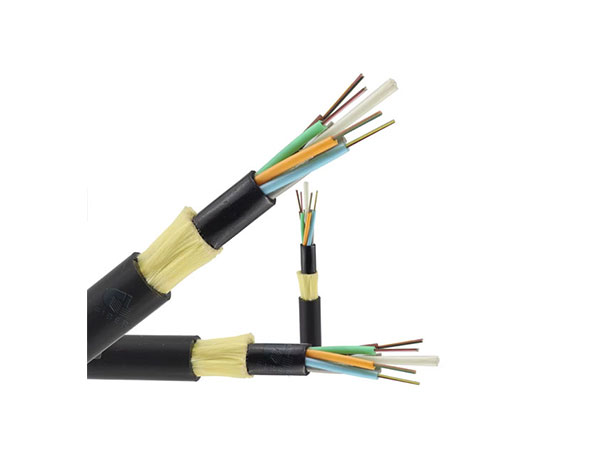

ADSS Aerial Double-Sheath Supported fiber optic cables are designed for aerial installations, providing high-quality data transmission in various environments. These cables are particularly well-suited for long spans that require durability and flexibility.

The double-sheath design of ADSS cables enhances protection against environmental factors and mechanical stress.

The outer sheath provides an extra layer of security against Waterproof, UV radiation, and physical damage, ensuring a longer lifespan and reliable performance.

Small outer diameter, light weight, flame retardant, easy to peel off, and highly flexible, Tight-fitting dry structure facilitates construction and maintenance.

Good toughness and very high tensile modulus, suitable for long-distance pipeline laying.

High mechanical strength, improves the tensile strength of optical cables, Anti-interference, non-conductive, corrosion-resistant.

Best PE Outer Sheath: The sheath is made of new high-environmentally friendly PE material,Cold-resistant, heat-resistant, corrosion-resistant, strong gloss, beautiful and practical

ADSS fiber optic cables can support spans of varying lengths, typically ranging from 200m, 250m, 300m, 400m, 600m, Etc. depending on specific requirements and environmental factors. This flexibility makes them suitable for urban, suburban, and rural applications alike.

Structure and Technical Specifications Of ADSS Cables

1. ADSS single jacket

| fiber count | structure | fiber per tube |

losse tube diameter (MM) |

FRP/pad diameter (mm) | Thickness of outer jacket(mm) |

Ref. Outer

Diameter

(mm)

|

Ref. Weight

(kg/km)

|

|

| PE Jacket | AT Jacket | |||||||

| 4 | 1+5 | 4 | 1.9 | 2.0/2.0 | 1.7±0.1 | 9.8 | 80 | 90 |

| 6 | 1+5 | 6 | 1.9 | 2.0/2.0 | 1.7±0.1 | 9.8 | 80 | 90 |

| 8 | 1+5 | 4 | 1.9 | 2.0/2.0 | 1.7±0.1 | 9.8 | 80 | 90 |

| 12 | 1+5 | 6 | 1.9 | 2.0/2.0 | 1.7±0.1 | 9.8 | 80 | 90 |

| 24 | 1+5 | 6 | 2.0 | 2.0/2.0 | 1.7±0.1 | 9.8 | 85 | 95 |

| 48 | 1+5 | 12 | 2.0 | 2.0/2.0 | 1.7±0.1 | 10.0 | 88 | 98 |

| 72 | 1+6 | 12 | 2.2 | 2.0/2.0 | 1.7±0.1 | 10.5 | 98 | 108 |

| 96 | 1+8 | 12 | 2.2 | 2.0/3.4 | 1.7±0.1 | 12.0 | 122 | 135 |

| 144 | 1+12 | 12 | 2.2 | 3.0/7.2 | 1.7±0.1 | 15.2 | 176 | 189 |

Tips: all the specifications in the abolve table is approximate data, for more detals specifications,pls contact our salers.

2. ADSS double jacket

| fiber count | structure | fiber per tube |

losse tube diameter (MM) |

FRP/pad diameter (mm) | Thickness of outer jacket(mm) |

Ref. Outer

Diameter

(mm)

|

Ref. Weight

(kg/km)

|

|

| PE Jacket | AT Jacket | |||||||

| 4 | 1+5 | 4 | 1.9 | 2.0/2.0 | 1.7±0.1 | 12.0 | 125 | 135 |

| 6 | 1+5 | 6 | 1.9 | 2.0/2.0 | 1.7±0.1 | 12.0 | 125 | 135 |

| 8 | 1+5 | 4 | 1.9 | 2.0/2.0 | 1.7±0.1 | 12.0 | 125 | 135 |

| 12 | 1+5 | 6 | 1.9 | 2.0/2.0 | 1.7±0.1 | 12.0 | 125 | 135 |

| 24 | 1+5 | 6 | 2.0 | 2.0/2.0 | 1.7±0.1 | 12.0 | 128 | 138 |

| 48 | 1+5 | 12 | 2.0 | 2.0/2.0 | 1.7±0.1 | 12.5 | 130 | 140 |

| 72 | 1+6 | 12 | 2.2 | 2.0/2.0 | 1.7±0.1 | 13.2 | 145 | 155 |

| 96 | 1+8 | 12 | 2.2 | 2.0/3.4 | 1.7±0.1 | 14.5 | 185 | 195 |

| 144 | 1+12 | 12 | 2.2 | 3.0/7.2 | 1.7±0.1 | 16.5 | 212 | 228 |

Tips: all the specifications in the abolve table is approximate data, for more detals specifications, pls contact our salers.