Weather conditions: 25m/s wind speed + 0mm Ice Load

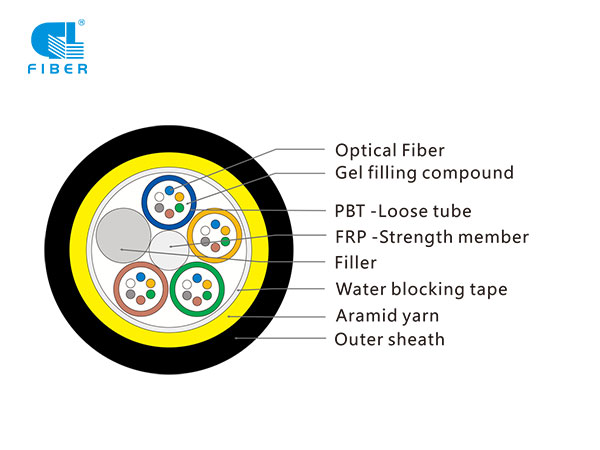

Cable Section Design:

Main Features:

1. High tensile strength

2. All dielectric structure and semi-dry core design

3. Small diameter and light weight

Application:

The design of ADSS cable takes full account of the actual situation of power lines and is suitable for different grades of high voltage transmission lines. Polyethylene ( PE ) sheath can be used for 10 kV and 35 kV power lines. For 110 kV and 220 kV power lines, the optical cable hanging point must be determined by calculating the electric field strength distribution and the electric mark ( AT ) outer sheath must be adopted. At the same time, the amount of aramid fiber and the perfect stranding process were carefully designed to meet the application requirements of different spans.

Standards:

IEC 60794-4、 IEC 60793、TIA/EIA 598 A

Optical Characteristics:

|

G.655 |

50/125μm | 62.5/125μm | |||

| G.652 | |||||

| Attenuation | @850nm | ≤3.0 dB/km | ≤3.0 dB/km | ||

| (+20℃) | @1300nm | ≤1.0 dB/km | ≤1.0 dB/km | ||

| @1310nm | ≤0.00 dB/km | ≤0.00dB/km | |||

| @1550nm | ≤0.00 dB/km | ≤0.00dB/km | |||

| Bandwidth(Class A) | @850nm | ≥500 MHz·km | ≥200 MHz·km | ||

| @1300nm | ≥500 MHz·km | ≥500 MHz·km | |||

| Numerical aperture | 0.200±0.015NA | 0.275±0.015NA | |||

| Cable Cutoff Wavelength | ≤1260nm | ≤1480nm | |||

| Cable Diameter | Cable Weight | Recommend maximum working tension | Maximum allowable working tension | breaking tenacity | Section area of tensile components | modulus of elasticity | thermal expansion coefficient ×10-6 /k | |

| mm | kg/km | kN | kN | kN | mm2 | kN/ mm2 | ||

| PE sheath | AT sheath | |||||||

| 9.8 | 121 | 130 | 1.5 | 4 | 10 | 4.6 | 7.6 | 1.8 |

| 10.2 | 129 | 138 | 2.1 | 5 | 14 | 6.9 | 8.1 | 1.4 |

| 13.1 | 132 | 143 | 2.8 | 7 | 19 | 9.97 | 9.13 | 1.2 |

| 15.6 | 189 | 207 | 3.8 | 9 | 26 | 14.2 | 11.2 | 1 |